- Metrology - Laboratory

- Inspection and Monitoring

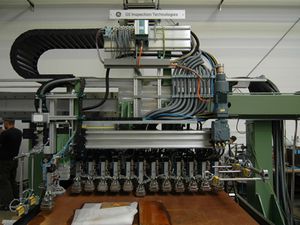

- Ultrasonic inspection system

- Waygate Technologies

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Ultrasonic inspection system ROWA™ Ux eddy currentautomatedquality control

Add to favorites

Compare this product

Characteristics

- Technology

- ultrasonic, eddy current

- Operational mode

- automated

- Type

- quality control

- Applications

- for the automotive industry, for NDT, for the aerospace industry

- Product applications

- for wires, for bars

Description

Solutions for the ultrasonic inspection of long steel products

Waygate Technologies' line of Krautkrämer ROWA™ Ux industrial automated UT systems are the most compact and simplistic solution for the full-body inspection of bars, billets and wire stock made from (stainless) steel alloys, aluminum, brass, and titanium on the market.

The system is designed for the highest quality requirements and meets all common ultrasonic inspection standards such as ISO 18563, AMS2154 Class AA, NADCAP as well as the industrial standards of the automotive and aviation industries. The compact dimensions of the mechanics enable for the most cost- effective integration into existing or new inspection lines. The optionally available reference standard manipulator “RSM” also enables a fully automatic, 100% reproducible sensitivity adjustment without any operator influence

Ultrasonic inspection of bar and wire starts here

Non-destructive testing (NDT) of bar stock is subject to constantly increasing demands concerning the quality of the test. This applies to bright precision steel and special bar quality (SBQ) levels as well as to hot-rolled black steel bar and wire, which often are used as a semi-finished product for cold-drawn bars.

Until the mid-2000s, eddy current inspection only was still sufficient to meet the quality requirements of the automotive industry. Today, non-destructive ultrasonic testing has become a standard method for most material qualities.

Catalogs

ROWA™ Ux

4 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Airshow China Zhuhai 2024 - China International Aviation / Aerospace Exhibition

12-17 Nov 2024 Zhuhai (China)

More information

Other Waygate Technologies products

Automated Ultrasonic Testing

Related Searches

- Digital camera module

- Visible camera system

- Full-color camera system

- High-definition camera

- Waygate Technologies inspection system

- CCD video camera

- High-performance camera module

- Spark optical emission camera system

- Endoscope

- Inspection machine

- Waygate Technologies automatic inspection system

- Flexible endoscope

- Zoom camera module

- Video endoscope

- Portable endoscope

- Flexible video endoscope

- Quality inspection system

- Automatic inspection machine

- Industrial video endoscope

- Portable video endoscope

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.