- Products

- Catalogs

- News & Trends

- Exhibitions

Modular materials handling system HS series for woodfor automatic tool changersfor conveyor belts

Add to favorites

Compare this product

Characteristics

- Operating mode

- modular

- Product applications

- handling, workpiece, stacking, industrial, pallet, for automatic tool changers, for conveyor belts, for wood, metal

- Applications

- process

Description

Our modular palletizing and sorting system offers comprehensive solutions for sorting, stacking and handling workpieces. Originally developed as a follow-up process to the WEBER sanding machine, it serves as a seamless interface to further processing steps. In addition, our system enables conveyor belts to be unloaded independently of the upstream machining process.

Unloading conveyor belts of all kinds

Our handling systems, consisting of the core components industrial robot, optical recognition system and conveyor belt, localize and identify the workpieces entering the cell. These are taught in fully automatically by the system and placed intelligently on a Euro pallet.

Human Machine Interface

The operator can easily activate teach mode and monitor the current process via the "Rob Simple Control" touch panel user interface. These are gripped intelligently depending on the workpiece's center of gravity and geometry. The gripping point of the workpieces is automatically recognized by the system so that the operator does not need any programming or robot knowledge. This process has been patented!

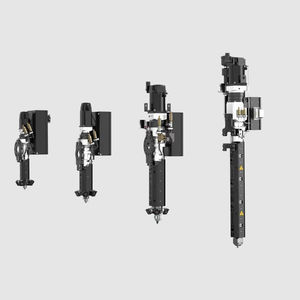

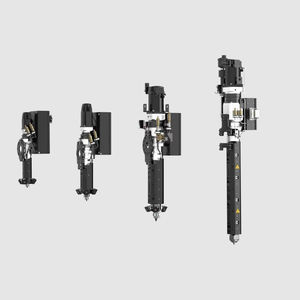

Automatic tool changer

The system can be equipped with various tools to ensure the handling of a wide range of workpieces. The gripping point is determined autonomously with the entire tool portfolio, without the machine operator having to perform a single work step.

Thanks to their modular design, our handling systems can be easily integrated into a wide variety of predecessor machines. By integrating a roller conveyor into the handling cell, it is possible to combine it with a pallet station, which in turn enables complete automation of production.

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.