DISCOVER NEW POSSIBILITIES FOR ADVANCED 3D PRINTING WITH CERAMIC RESIN - EXPERIENCE THE EXCEPTIONAL HEAT RESISTANCE, EXTREME RIGIDITY AND DISTINCTIVE AESTHETICS OF CERAMIC FOR A WIDE RANGE OF PROFESSIONAL, INDUSTRIAL AND TECHNOLOGICAL APPLICATIONS.

PROS

Ceramic-like look and finish

Homogenous matt finish

High elastic modulus

High thermal resistance

CONS

Low impact resistance

MAIN FEATURES

3D Printing process: MSLA

Tolerances: ± 0,60mm 100mm

Max size: 280 x 165 x 400 mm ; 11 x 6.5 x 15.7 in

Lead time: <2 days

LOOK AND FINISH

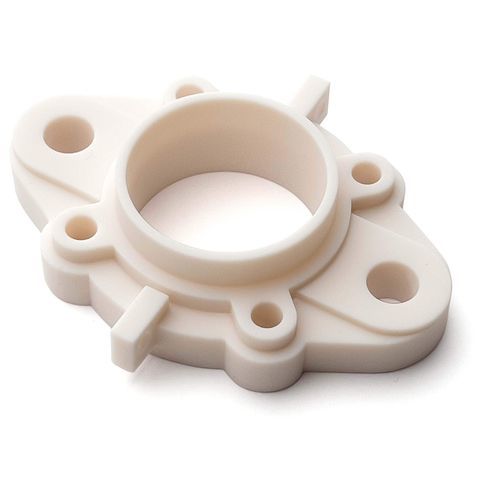

In addition to its mechanical properties, it offers a unique aesthetics reminiscent of traditional ceramics. This adds a quality touch to the moulded parts, making them not only functional, but also aesthetically pleasing.

HOMOGENEOUS MATT FINISH

Pieces moulded with this material have a smooth, uniform and matt surface finish. This aesthetic quality enhances the visual appeal of moulded parts, giving them an elegant, ceramic-like appearance.

HIGH THERMAL RESISTANCE

The material is designed to withstand high temperatures without compromising the structural integrity of the moulded parts. This makes it an ideal choice for applications such as electronic housings or wind tunnel test models, where the part may be exposed to high temperatures.

The new Ceramic Resin is an innovative addition to our range of 3D printing materials. Designed for high heat resistance and high elastic modulus, this composite white ceramic resin offers unique functional and aesthetic qualities.

PROS

• Ceramic look and feel

It aesthetically presents a unique, uniform matt finish that offers a ceramic-like look and feel.