PEEK 3D printing FDMindustrial

Add to favorites

Compare this product

Characteristics

- Materials to be printed

- PEEK

- Technology

- FDM

- Applications

- industrial

Description

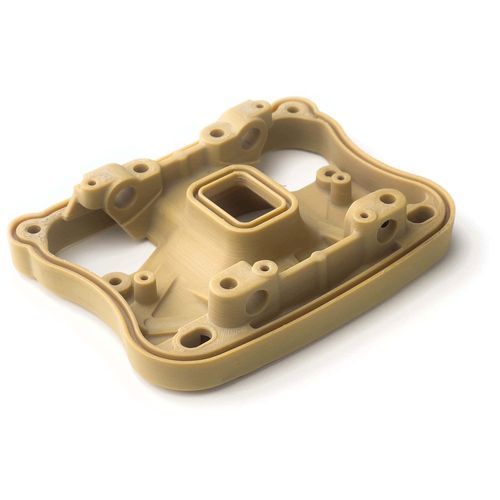

PEEK IS A POLYMER USED IN THE INDUSTRIAL AND AEROSPACE FIELDS WITH EXCEPTIONAL MECHANICAL PROPERTIES, VERY SIMILAR TO THOSE OF SOME METAL ALLOYS. IN ITS FILAMENT-PROCESSED VERSION, IT ALLOWS COMPLEX GEOMETRIES TO BE OBTAINED, LEAVING THE DESIGNER FREE FROM MOST OF THE LIMITATIONS OF TRADITIONAL PRODUCTION TECHNOLOGIES.

PROS

Excellent mechanical performance

Excellent resistance to high temperatures and chemicals

Flame retardant

The best option for Metal Replacement cases

CONS

Not uniform properties on all axes

Challenging to print

Most expensive compared to other 3D printing materials

Low impact resistance

MAIN FEATURES

Tolerances: 100mm ± 0,75%

Max size: 300 x 300 x 400 mm; 11,8 x 11,8 x 15,8 in

Lead time: <3 days

EXCELLENT MECHANICAL STRENGTH

With its exceptional mechanical properties, PEEK stands out as a top choice. Its remarkable strength, makes it the ideal material for components that need to endure significant mechanical stress.

THERMAL STABILITY

With its exceptional heat resistance, this thermoplastic is the preferred choice for applications that require the ability to withstand high temperatures while maintaining their structural integrity.

With its remarkable resistance to a diverse range of chemicals, PEEK proves to be the perfect choice for applications in demanding environments, where the degradation of other materials is a concern.

PEEK is an impressive high-performance thermoplastic used in 3D printing with FDM (Fused Deposition Modeling) technology. It presents an exceptional blend of properties, providing unparalleled mechanical strength, thermal stability, and chemical resistance.

Catalogs

No catalogs are available for this product.

See all of Weerg‘s catalogsRelated Searches

- Machining service

- Milling machining

- CNC milling machining

- ISO machining

- Automotive milling machining

- Medical milling machining

- 3D printing

- Plastic milling machining

- Plastic 3D printing

- Machining for the aerospace industry

- Industrial 3D printing

- Electronic milling machining

- Prototyping 3D printing

- Milling machining for the food industry

- Medical 3D printing

- FDM 3D printing

- 3D printing for the automotive industry

- 3D printing for the aerospace industry

- 3D printing for the electronics industry

- Resin 3D printing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.