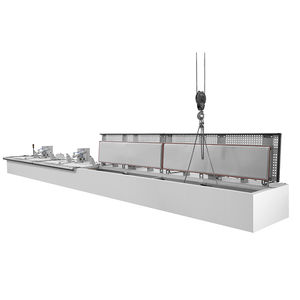

Cabinet oven VTU seriesdryingelectricindustrial

Add to favorites

Compare this product

Characteristics

- Configuration

- cabinet

- Function

- drying

- Heat source

- electric

- Other characteristics

- industrial

- Maximum temperature

200 °C

(392 °F)

Description

In projects with blue chip customers such as Airbus Helicopters, DLR and GKN Aerospace, our experience in building special systems was the decisive factor.

Our focus:

• Short process times through high heating and cooling rates

• Ensuring high-quality products through homogeneous temperature distribution in the oven

• Reproducibility by use of components with consistently high quality

• 100 % traceability via networked control

• Systems that are optimally adjusted to the production processes through the development of customerspecific solutions Helicopter cockpits, carrier rocket fuselages and the doors of the A350 XWB are just a few of the products moulded in our ovens.

Catalogs

No catalogs are available for this product.

See all of Weiss Technik‘s catalogsRelated Searches

- WEISS TECHNIK oven

- WEISS TECHNIK chamber oven

- Electric furnace

- Heat treatment furnace

- Drying furnace

- Combustion furnace

- Gas furnace

- Tunnel furnace

- Baking oven

- Industrial furnace

- Continuous furnace

- Air circulating furnace

- Horizontal furnace

- Sintering furnace

- Conveyor furnace

- Heat sterilizer

- Tempering furnace

- Cabinet furnace

- Process sterilizer

- Infrared furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.