When special materials, such as 904L, 6Mo or similar, are in demand for their resistance to aggressive media, the pipes can often be acquired only in dimensions pursuant to ASME B36.10 (schedule dimensions).

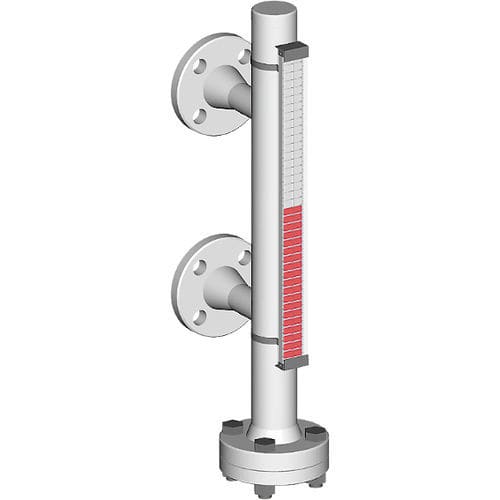

Here, the PetroLine gets a chance, with pressure ratings from 20 bar to 150 bar (2 MPa to 15 MPa) as standard. The name already indicates which industry is served with its special media and requirements.

The entire design is tailored towards the ASME standard but also covers the requirements of the European Pressure Equipment Directive (PED). If full X-ray capacity of all welded seams is required, the direct side connections are replaced by T-pieces. Thus, all applicable, non-destructive test methods can be used.

In the LowDensity version, fluids with densities as of 0.32 g/cm3 can already be displayed.

The float with the lying bar magnet serves as a basis here as well. Many years ago, WEKA was the first manufacturer to develop the spherical float. Owing to the optimally pressure resistant geometry of the sphere, a float could be designed in titanium that is suitable for the highest pressures without increasing the internal pressure. Thus, WEKA can choose between a large number of float types for diverse parameters.

WEKA offers specialised products for your branch of industry!

Whether flange, thread or welding ends, the basic type including connections can be determined with simple pressure/temperature diagrams (p/T diagrams). Since there is the suitable float for all types, which WEKA chooses according to the process data, all that remains is the selection of the gauge bar, whose variety is available for all types.