- Products

- Cladding machine

- Welding Alloys Group

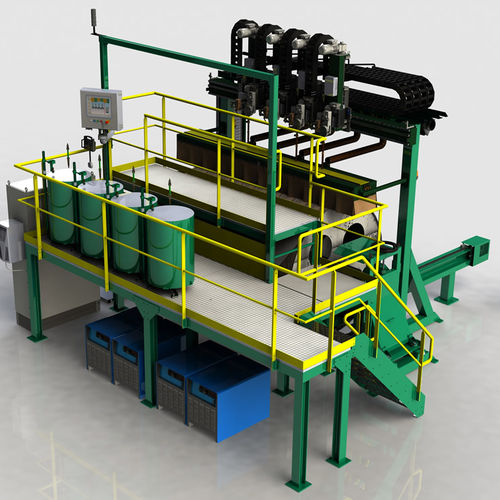

Cladding machine

Add to favorites

Compare this product

Description

High performance, top-quality plate cladding

The Rotary Plate Cladder machine is a heavy duty welded base assembly with two, three, four or more welding heads, built for hard work. Two or more plates are mounted on a drum and hardfaced continuously, which ensures maximum productivity.

Industries: cement, steel, mining, power, security, agriculture, recycling

Characteristics

Dedicated for plate cladding applications

Heavy duty construction

D3 Touch control unit

Constant surface speed

Open-arc welding

Dimensions up to 3 x 12 meters

Benefits

Achieves perfect quality welded materials

Maximum productivity (0,7m²/h for a 6+4 plate with 2 heads and Ø2.8mm wire)

Easy operator interaction

Different welding beads: stringer beads, oscillated, sine waves

Adaptable for various welding processes

Specifications

Heavy duty welding – flux cored wire diameter 1.0 – 4.0mm

Wire dispensed from spools or drums

Interface with rotary device

Spindle device

Drum up to 8 tons

Linear movement - double motorised carriage assembly mounted on beams:

speed 0.5 – 3m/min (horizontal)

speed 0.5 – 2m/min (vertical)

Options

Water cooled welding kit

Additional welding head

Twin wire-feed unit with wire straightener

Fast oscillators

Interface with power source

Fume extraction

Drop carbide hoppers

Gas shielded welding gun kit

Sub-arc welding kit

Catalogs

No catalogs are available for this product.

See all of Welding Alloys Group‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.