- Products

- Catalogs

- News & Trends

- Exhibitions

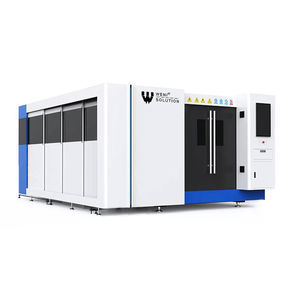

Fiber laser cutting machine WS GMfor metalfor metal sheetstube

Add to favorites

Compare this product

Characteristics

- Technology

- fiber laser

- Material

- for metal

- Product handled

- for metal sheets, tube, profile

- Control type

- with control software

- Other characteristics

- automatic

- X travel

3,000 mm, 4,000 mm

(118.11 in, 157.48 in)- Y travel

1,500 mm

(59.06 in)- Z travel

220 mm

(9 in)- Cutting speed

80 m/min

- Laser power

Max.: 4,000 W

Min.: 1,000 W

- Overall length

4,445 mm, 5,460 mm

(175 in, 215 in)- Overall width

2,440 mm, 2,445 mm

(96 in, 96 in)- Height

2,100 mm

(83 in)- Weight

4,460 kg, 4,600 kg

(9,832.62 lb, 10,141.26 lb)

Description

The WS-GM Basic model is aimed at customers with medium-volume production who also want to cut pipes and profiles up to 3 or 6m in length. Raycus and IPG laser generators from 1000W are available for this model. These models are characterized by an open work table, available in as many as six sizes: 2500x1300mm, 3000x1500mm, 4000x1500mm, 4000x2000mm, 6000x1500mm, 6000x2000mm. All axes are driven by the brand's servo motors Schneider which are characterized by high accuracy and durability. The device has an efficient laser function Autofocus, stable software CypCut with function NESTING(automatic optimization of project placement on the material), dual cooling system, lubrication system and dust extraction system. Due to the use of structures with significant reduction of vibrations, the WS-GM Basic models are characterized by high rigidity, stability and resistance to shocks, and the processed materials retain the set parameters. Pneumatic clamp Facilitates center positioning / adjustment of pipe or profile clamp for further processing. It covers the profile in two directions and automatically implements profile alignment. The use of this modern option as standard devices saves time, as there is no need for manual clamping. BASIC series devices also include as standard:

• computer in a configuration that ensures the functionality of the device,

• two gas lines (the first electronically controlled, the second manually - optionally, you can also choose automatic control of this line),

• exhaust extraction,

• basic limit sensors and software protection,

• basic ball rollers for supporting plate loading.

VIDEO

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Automatic cutting system

- Sheet metal cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Precision cutting system

- Fabric cutting system

- Sheet cutting system

- Three-phase cutting system

- Engraving cutting system

- Bridge cutting system

- CO2 laser cutting system

- Wood cutting system

- High-power cutting machine

- Stone cutting system

- Cutting system with water cooling

- Profile cutting center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.