- Products

- Catalogs

- News & Trends

- Exhibitions

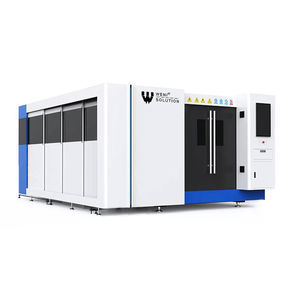

Fiber laser cutting machine WS-6020Tfor metaltubeprofile

Add to favorites

Compare this product

Characteristics

- Technology

- fiber laser

- Material

- for metal

- Product handled

- tube, profile

- Control type

- with control software

- Phase

- three-phase

- Y travel

5,850 mm

(230.31 in)- Z travel

220 mm

(9 in)- Tube diameter

Max.: 220 mm

(9 in)Min.: 20 mm

(1 in)- Laser power

Max.: 2,000 W

Min.: 1,000 W

- Overall length

13,474 mm

(530 in)- Overall width

4,757 mm

(187 in)- Height

2,398 mm

(94 in)- Weight

5,500 kg

(12,125.42 lb)

Description

Professional laser cutting machine designed for processing pipes and profiles. The T series is characterized by high speed, up to 60m/min, and high working precision, up to ±0.02mm. The laser is equipped with pneumatic clamps, a receiving table and an automatic loading option. The device features a fully opening housing, powerful laser, Autofocus function, stable CypTube software, dual cooling system, voltage stabilizer, lubrication system and dust collection system.

The use of heavy construction made of high-quality metal alloys and subjecting it to long, special processing removes the resulting stresses in the material and significantly reduces vibration, shock and vibration, so that the WS-T series is characterized by high rigidity, stability and shock resistance, and the processed materials maintain the set parameters.

The T-series allows processing of pipes and profiles up to 6000mm long. After processing, only 15cm of material is left for Φ 80mm in the rear clamp. The machine uses the most accurate cutting method and a material guidance and control system. The fabric is attached with a sliding rear handle and a guiding front handle. The clamps in the spindle holders are pneumatic, which significantly speeds up the loading and handling process.

VIDEO

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Automatic cutting system

- Sheet metal cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Precision cutting system

- Fabric cutting system

- Sheet cutting system

- Three-phase cutting system

- Engraving cutting system

- Bridge cutting system

- CO2 laser cutting system

- Wood cutting system

- High-power cutting machine

- Stone cutting system

- Cutting system with water cooling

- Profile cutting center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.