- Products

- Catalogs

- News & Trends

- Exhibitions

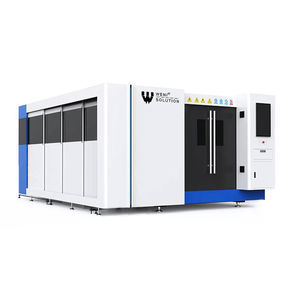

Fiber laser cutting machine WS-6020TMfor metalfor metal pipeswith control software

Add to favorites

Compare this product

Characteristics

- Technology

- fiber laser

- Material

- for metal

- Product handled

- for metal pipes

- Control type

- with control software

- Phase

- three-phase

- Configuration

- 5-axis

- Other characteristics

- automatic

- Y travel

7,230 mm

(284.65 in)- Z travel

185 mm

(7 in)- Tube diameter

Min.: 15 mm

(1 in)Max.: 220 mm

(9 in)- Cutting speed

80 m/min

- Laser power

Min.: 1,000 W

Max.: 6,000 W

- Overall length

9,100 mm

(358 in)- Overall width

1,700 mm

(67 in)- Height

2,050 mm

(81 in)- Weight

6,000 kg

(13,227.74 lb)

Description

The 2nd Generation WS-T model with 5-axis head is all about a reinforced design and even greater precision and cutting speed. The new version features innovative solutions based on the best quality components and systems, which combine to create a reliable High-Tech device that will work well in any advanced production facility. The cutter has a dual cooling system, an automatic lubrication system and an efficient system for extracting the resulting exhaust fumes. The improved skeleton takes care to minimize vibrations and features high rigidity, stability, and longevity.

Automate the production process

Unlike the previous generation, we added the ability to expand the machine with an automatic loading system, which saves operators' time in the first place, speeds up the production process and makes the cutter a fully automated system for processing spherical objects. It is a system based on overhead cranes, motors and drive belts, which transfer the material to the clamps at high speed.

Precision and repeatability of pneumatic clamps

In this version, we used reliable pneumatic chucks that take care of precision during rotation, while keeping the material intact throughout the machining process. The fabric is clamped with the sliding rear handle and the guiding front handle. In addition, we have introduced a material collection system after processing, which makes it easier to deliver ready-made items to the storage site.

Servo drives support - positioning system

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Automatic cutting system

- Sheet metal cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Precision cutting system

- Fabric cutting system

- Sheet cutting system

- Three-phase cutting system

- Engraving cutting system

- Bridge cutting system

- CO2 laser cutting system

- Wood cutting system

- High-power cutting machine

- Stone cutting system

- Cutting system with water cooling

- Profile cutting center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.