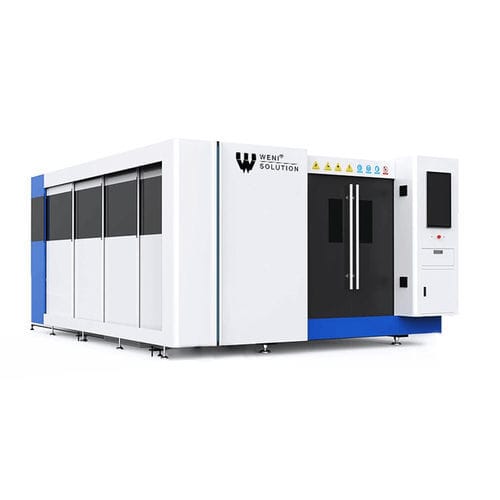

Professional, enclosed laser cutters with dimensions of 3000x1500mm or 4000x1500mm, 4000x2000mm, 6000x2000mm and power from 1000W IPG / Raycus, characterized by high speed and the best parameters . The control system is located in a separate, free-standing cabinet, so it is not exposed to damage and disturbances related to the operation of the device, and facilitates the operation of the device. All axes are driven by the brand's latest servo motors Schneider , which are characterized by high accuracy and very high durability. The device has an efficient laser function auto-focus , stable software CypCut with function NESTING (automatic optimization of project placement on the material), dual cooling system, lubrication system and dust extraction system. The use of heavy construction, made of high-quality metal alloys and its long-term and special treatment, eliminates the stresses in the material, which significantly reduces vibrations, shocks and vibrations, thanks to which the processed materials maintain the indicated parameters. The standard PRO series devices also include:

• A computer with a fast processor and large amount of memory - allows you to perform faster nesting in the cutting program.

• touch, modern screen,

• lighting of the head and working area,

• limit sensors on both axes with software protection,

• electronic, zonal exhaust extraction system,

• ball rollers for supporting plate loading,

• reinforced guiding covers.