- Products

- Catalogs

- News & Trends

- Exhibitions

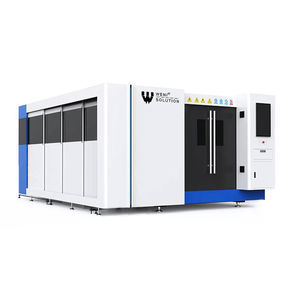

Fiber laser cutting machine WS FCM PROfor metalprofilefor metal pipes

Add to favorites

Compare this product

Characteristics

- Technology

- fiber laser

- Material

- for metal

- Product handled

- for metal sheets, for metal pipes, profile

- Control type

- CNC

- Phase

- three-phase

- X travel

1,500 mm, 2,000 mm

(59.06 in, 78.74 in)- Y travel

3,000 mm, 4,000 mm

(118.11 in, 157.48 in)- Z travel

200 mm

(8 in)- Cutting speed

100 m/min

- Laser power

Min.: 1,000 W

Max.: 4,000 W

- Overall length

4,500 mm, 5,650 mm

(177 in, 222 in)- Overall width

2,290 mm, 2,900 mm

(90 in, 114 in)- Height

2,100 mm

(83 in)- Weight

2,580 kg, 4,125 kg

(5,687.93 lb, 9,094.07 lb)

Description

A series of professional laser cutters with a spindle and a closed table with dimensions: 3000x1500mm, 4000x1500mm, 4000x2000mm, 6000x2000mm and power from 1000W IPG / Raycus, addressed to customers who want to cut also pipes and profiles with a length of 3 or 6 m, with casing. The control system is located in a separate freestanding cabinet, so it is not exposed to damage and interference associated with the operation of the device, and facilitates the operation of the device. All axes are driven by the brand's latest servo motors Schneider , which are characterized by high accuracy and very high durability. The device has an efficient laser function auto-focus , stable software CypCut with function NESTING (automatic optimization of project placement on the material), dual cooling system, lubrication system and dust extraction system. The use of heavy-duty construction made of high-grade metal alloys and subjecting it to long-time and special processing eliminates the resulting stresses in the material, which significantly reduces vibration, shock and oscillation, so that the processed materials maintain the indicated parameters. The pneumatic clamp makes it easy to set/adjust at the center of the clamp a pipe or profile for further processing. It covers the profile in two directions and automatically implements profile alignment. The use of this modern option as standard devices saves time, as there is no need for manual clamping. The standard PRO series devices also include:

• computer with a fast processor and plenty of memory - allows you to carry out faster nesting in the clipping program,

• touch, modern screen,

VIDEO

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Automatic cutting system

- Sheet metal cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Precision cutting system

- Fabric cutting system

- Sheet cutting system

- Three-phase cutting system

- Engraving cutting system

- Bridge cutting system

- CO2 laser cutting system

- Wood cutting system

- High-power cutting machine

- Stone cutting system

- Cutting system with water cooling

- Profile cutting center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.