- Products

- Catalogs

- News & Trends

- Exhibitions

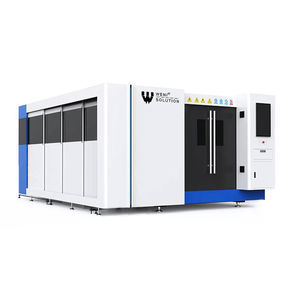

Fiber laser cutting machine WS3015HM for metaltubeprofile

Add to favorites

Compare this product

Characteristics

- Technology

- fiber laser

- Material

- for metal

- Product handled

- tube, profile, sheet

- Control type

- with control software

- Phase

- three-phase

- Configuration

- double table

- X travel

3,000 mm

(118.11 in)- Y travel

1,500 mm

(59.06 in)- Z travel

220 mm

(9 in)- Cutting speed

100 m/min

- Laser power

3,000 W, 6,000 W

- Overall length

8,210 mm

(323 in)- Overall width

2,730 mm

(107 in)- Height

2,350 mm

(93 in)- Weight

8,000 kg, 15,000 kg

(17,636.98 lb, 33,069.34 lb)

Description

The WS3015HM PRO model is now available in our showroom -

WS-HM series with high power "High Power", with an additional loading platform and full housing, which in practice means two interchangeable work tables working alternately, thus using the full production speed of the device. Additionally, each device is equipped with a spindle that enables cutting pipes and profiles up to 6 m.

FREE - a gift voucher worth PLN 1,000 for the purchase of accessories and consumable parts to be used at the Weni Store.

This model is equipped with a Raytools head with Autofocus function, Schneider servo drives, CWFL6000 cooling, SMC valves and a 50kva voltage stabilizer

The perfect solution for full-size production, where the time of material processing is a priority. The H series enclosure has a 4-chamber exhaust system, a fully sliding front door, and an additionally installed camera with an LCD monitor allows you to monitor the machining process. The laser has two open tables with a working area of 3000x1500mm and is equipped with a 3000W laser.

Characterized by high speed and the best parameters. The control system is located in a separate, free-standing cabinet, so it is not exposed to damage and disturbances related to the operation of the device, and facilitates the operation of the device. All axes are driven by the brand's latest servo motors Schneider , which are characterized by high accuracy and very high durability.

VIDEO

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Automatic cutting system

- Sheet metal cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Precision cutting system

- Fabric cutting system

- Sheet cutting system

- Three-phase cutting system

- Engraving cutting system

- Bridge cutting system

- CO2 laser cutting system

- Wood cutting system

- High-power cutting machine

- Stone cutting system

- Cutting system with water cooling

- Profile cutting center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.