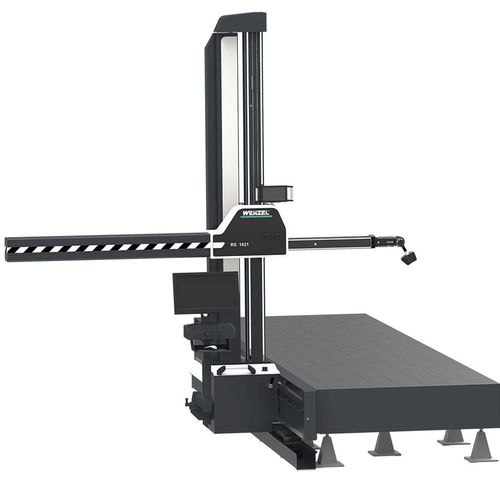

The machine concept of the RS series is based on a stable base plate as a measuring table with a laterally mounted guide system.

Highly flexible, the RS can be integrated into an existing room concept without a specific foundation and can be moved to a new location if required.

Features

High flexibility

Simple and flexible integration into existing room and building concepts | Adaptive in case of room, building and process changes

High durability

Machine design with wear-resistant and optimised components | Investment protection through upgradeability and compatibility

High ease of maintenance

Original manufacturer service | Optimal accessibility | Low downtime

You have the choice

Base plate available in cast iron or granite | Optionally with active vibration damping | Different operating modes

Wide range of applications

Also suitable for small parts due to ergonomic working height | Measurement during production

Industrial computed tomography

It is available as a manual or CNC device as well as combined with disengageable drives, as a single, double or multiple column system, with tactile and optical sensor technology and also with vibration damping. The RS allows production-related measurement of individual parts, assemblies, end products such as car bodies and other large-volume workpieces. The RS is available in two accuracy classes - Standard and Premium.

Areas of application

The main areas of application for the RS series are in the automotive industry for measuring, digitising and marking out individual parts, assemblies or complete car bodies. Typical components are e.g. bumpers, seats, dashboards, welded constructions or fixtures.