Introduction

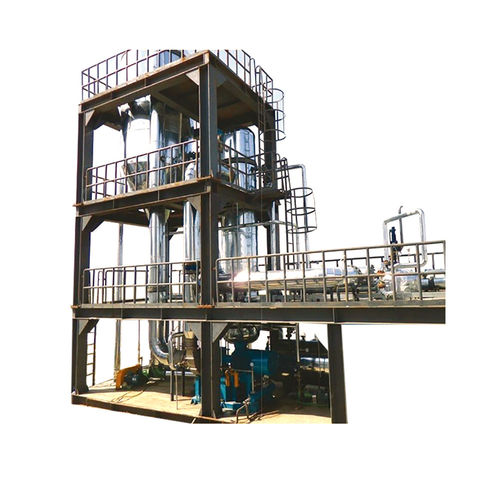

Mechanical vapor recompression (MVR) evaporator is using high efficiency steam compressor to compress the secondary steam of the evaporator. The pressure and temperature of vapor are increased, and be sent back to the heating chamber as the heating source. The liquid material is keeping in boiling state, while the heating vapor is converted into condensate water. So that it has made full use of the steam, and recycled the latent heat, improves the thermal efficiency.

Main features:

1. Low energy consumption, low operating cost. MVR technology is most advanced evaporator, need only very little live steam during startup. Meanwhile It reduces the environmental pollution.

2. Due to compressor provides the heating source , the temperature differences is small, so that achieves moderate evaporation, reduce the possibility of occurring scale, improve the product quality.

3. MVR evaporator is material evaporating in low temperature ((50C-100C), and no bubbles produced under the status of evaporation , so that ensure no material goes out with bubbles , and the material is not easy to coking, saves the maintenance cost.

4. Without condenser or just a small condenser, saves cooling water and installation area.

5. with CIP system, which can realize in place cleaning, the complete set of equipment is easy to operate, no dead angle.

6. Automatic operation system, uses PLC and industrial computer to control the operation process, make the parameters setting , monitoring and recording, reduce the labor intensity of workers

Capacity: Evaporation capacity from 0.5T/hr to 200T/hr, and can be designed according the specification of the feed material.