- Industrial machines and equipment

- Heat Exchanger and Refrigeration

- Steam boiler

- Wenzhou Jhenten Machinery Co., Ltd.

Steam boiler JTRZG serieselectricverticalindustrial

Add to favorites

Compare this product

Characteristics

- Product

- steam

- Power source

- electric

- Configuration

- vertical

- Other characteristics

- industrial

- Pressure

1 bar

(14.5 psi)

Description

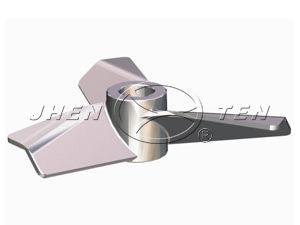

JTRZG Jacketed Steam Kettle

Steam kettle hâve double-layer structure, and jacket uses steam or heat conduction oil as a heating medium. Steam kettle can use installed flange discharge, and material can be directly discharging after steaming. It is a convenient operation. Kettle body adopts circular arc transition, no dead corner, easy to clean; mirror polishing Processing meets sanitary standard.

Jacket kettle can be fixed structure or tiltable structure, also can add mixing device and émulsification device according to customers' requirements.

Tank Optional Configuration

Jacketed Steam Kettle can configure thermometer(Digital display or Dial type), pressure gauge, sight glasses, sanitary manhole, liquid in-outlet, CIP cleaning bail and so on, also can configure as customers' requirement.

Feature

• - Jacketed kettle hâve large heating area, high thermal efficiency, even heating advantage, short boiling time and easy control of heating température. It is a good equipment to improve quality, shorten time and improve working conditions on food Processing.

• - Volume:50L~500L and multiple spécification, also we can design and manufacture according to customers' requirement.

• - The connection adopts Tri-clamp, the tanks' inner use 304 or 316L. The inner surface mirror polishing Ra<0.28pm ~ 0.6pm. Outer surface can be polished, wiredrawn, sandblasted according to customer's requirement.

Application

• - Used for the Processing of various kinds of food, specially used in large restaurant or dining room to boil soup, cook, stew, boil congee, etc.

• - Used in liquid configuration, décoction and concentration in pharmaceutical, food, Chemical industry and light industry.

Catalogs

No catalogs are available for this product.

See all of Wenzhou Jhenten Machinery Co., Ltd.‘s catalogsOther Wenzhou Jhenten Machinery Co., Ltd. products

Clean Containers

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.