- Industrial machines and equipment

- Surface Treatment Equipment

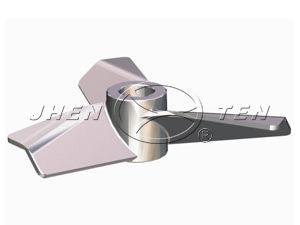

- Emulsification tank

- Wenzhou Jhenten Machinery Co., Ltd.

Emulsification tank JTRRG seriesfor high-viscosity productsfor paint and inkfor chemicals

Add to favorites

Compare this product

Characteristics

- Function

- emulsification

- Product applications

- for high-viscosity products, for paint and ink, for chemicals, for food, for cosmetic products, for industrial applications

- Material

- stainless steel

- Other characteristics

- vertical

- Capacity

Min.: 600 l

(158.503 gal)Max.: 5,000 l

(1,320.86 gal)- Pressure

Min.: -1 bar

(-14.5 psi)Max.: 6 bar

(87 psi)

Description

The Emulsification Tank adopts Vertical circular tanks, both of top and bottom are standard oval and torispherical head. Transition section in tank using circular arc transition, without dead corner, easy to clean. Heating mode with steam, electric heating, heat conduction oil, equipped with mechanical stirring according to customers' requirement.

Tank Optional Configuration

The Crystallizing Tank can select 0.2pm hydrophobie stérile air filter, thermometer(Digital display or Dial type), 2 sight glasses, steam sterilization hole, sanitary manhole, liquid in-outlet, CIP rotating cleaning bail, liquidometer and Liquid level control system(Bearing module, non-contact ultrasonic, static pressure transmitting device) and so on, also can configure as customers' requirement.

Application

• Suitable for cosmetic, medicine, food, Chemical, dyeing, printing ink and other industrial production, especially for high matrix viscosity, solid material content higher material préparation émulsion will be more efficacy.

Feature

• - Volume:600L~20000L and multiple spécification, also can design and manufacture according to customers' requirement.

• - Jacket can pass steam (or hot water), can also pass the cooling water. Jacket has disk tubular, full jacketed and Maitreya plate. Jacketed outside covered with insulation, thermal insulation material for rock wool (warm) or PU (cold).

• - The connection adopts Tri-clamp, the tanks' inner use 304 or 316L. The inner surface mirror polishing Ra<0.28pm ~ 0.6pm, outer surface can polishing, wire drawing and sandblasting according to customers' requirement.

Catalogs

No catalogs are available for this product.

See all of Wenzhou Jhenten Machinery Co., Ltd.‘s catalogsOther Wenzhou Jhenten Machinery Co., Ltd. products

Clean Containers

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.