- Food industry

- Other Food Machinery

- Sugar dissolver

- Wenzhou Jhenten Machinery Co., Ltd.

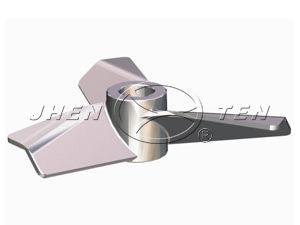

Sugar dissolver ACT series

Add to favorites

Compare this product

Characteristics

- Options

- sugar

Description

Detail Description

Dissolving Tank

In the beverage industry, sugar is mostly processed as a watery solution. Therefore, the first step is the production of a standardized sugar syrup. The concentration is between 60 ... 67° Brix. Discontinuous and continuous processes are applied in the beverage industry.

Discontinuous process with Dissolving Tank

For discontinuous processes mixers are used, the capacity of which can vary according to the prepared granular sugar quantity. The required quantity of well-tempered dissolving water is provided in the mixer. By means of a pneumatical or mechanical conveyor the granular sugar is fed to the mixer. When the dissolving procedure is finished, the sugar syrup is filtered and pasteurised and then, in a filtered condition, passed on to a buffer tank.

Continuous process with hot/cold dissolving tank

The continuous processes can be divided into cold and hot dissolving procedures. These procedures require a granular sugar silo and a corresponding tank capacity for sugar syrup. Granular sugar and dissolving water are fed to the dissolving tank in the desired ratio. A circulating pump ensures a homogeneous suspension. A partial flow is supplied to the buffer tank, either via a gap filter (cold dissolving) or a pasteurisation (hot dissolving) with integrated filtration and deaeration.

Catalogs

No catalogs are available for this product.

See all of Wenzhou Jhenten Machinery Co., Ltd.‘s catalogsOther Wenzhou Jhenten Machinery Co., Ltd. products

Clean Containers

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.