- Products

- Low-temperature drying unit

- Wenzhou Jinbang Light Ind Machinery Co., Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

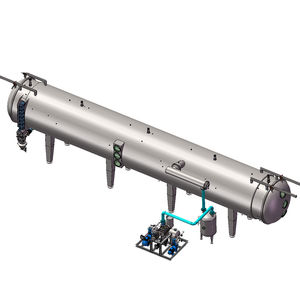

Drying unit for the food industry BVDlow-temperatureair conditioned

Add to favorites

Compare this product

Characteristics

- Options

- for the food industry, low-temperature, air conditioned

Description

JNBAN Belt Vacuum Drying (BVD) is a method of continuously distributing liquid raw materials on a conveyor belt under vacuum conditions.The materials are dried with the conveyor belt on the heating plate, and then cooled, embrittled and pulverized.

A low temperature drying method. During the whole drying process, the extract is in a vacuum, closed environment, and the drying process is mild(operating temperature 30-135° C), which can maintain its physical properties to the maximum extent and obtain a high quality final product.

Since the material is gradually dried under a vacuum for a period of time, the particles obtained by drying have a certain degree of crystallization effect, and at the same time, there are micropores inside from the microscopic structure.

After directly pulverizing to the required particle size, the flowability of the particles is very good, and it can be directly tableted or filled with mash, and the particles have good fast solubility.

Drying Capacity (kg):15-60kg/h

Voltage:3Phase/220v/380v/50Hz

Power:8KW

Dimension(L*W*H):7000*2600*4500mm

Key Selling Points:Sustainable

Warranty:3 years

Weight (KG):9200

Evaporation Capacity(kg/h):5.6-7.7 kg/h

Heating Method:Steam Heating

VIDEO

Catalogs

Vacuum Belt Dryer

7 Pages

Other Wenzhou Jinbang Light Ind Machinery Co., Ltd products

vacuum belt equipment and other products

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.