- Industrial machines and equipment

- Furnace and Heat Treatments

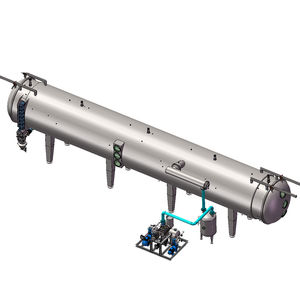

- Vacuum dryer

- Wenzhou Jinbang Light Ind Machinery Co., Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Vacuum dryer continuousfor the food industryfor the pharmaceutical industry

Add to favorites

Compare this product

Characteristics

- Technology

- vacuum

- Batch/continuous

- continuous

- Applications

- for the food industry, for the pharmaceutical industry, for the chemical industry

- Associated function

- clean-in-place (CIP)

- Other characteristics

- with belt conveyor, low temperature

Description

What are the benefits of drying Emamectin Benzoate with vacuum belt dryer?

Jinbang Vacuum Belt Dryer is a very suitable equipment for drying Emamectin Benzoate, low temperature vacuum continuous drying, high efficiency and high quality.

Drying Emamectin Benzoate with vacuum belt dryer has the following key benefits:

1. Low temperature drying: Vacuum belt dryers allow drying at relatively low temperatures, which helps to maintain the quality and chemical properties of the product. For heat sensitive substances like Emamectin Benzoate, low temperature drying is important to avoid decomposition or degradation.

2. Rapid drying: Vacuum belt dryers can remove water from the product in a relatively short period of time, increasing production efficiency. This is especially important for mass production.

3. Maintain product uniformity: The belt dryer ensures that products such as Emamectin Benzoate maintain a uniform temperature and humidity distribution throughout the drying process, which reduces the appearance of hot or cold spots and helps to minimize the risk of quality non-uniformity.

4. Avoiding oxidation: Under vacuum conditions, the belt dryer can effectively reduce the presence of oxygen, thereby reducing the risk of product oxidation. This is very beneficial for substances that are susceptible to oxidation.

5. Saving energy: Compared to traditional hot air drying methods, vacuum belt dryers usually require less energy because they are able to utilize heat more efficiently.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Wenzhou Jinbang Light Ind Machinery Co., Ltd‘s catalogsOther Wenzhou Jinbang Light Ind Machinery Co., Ltd products

vacuum belt equipment and other products

Related Searches

- Drying system

- In-line dryer

- Air blast drying system

- Drying system for the food industry

- Centrifugal dewatering system

- Vacuum drying system

- Drying system for the chemical industry

- Drying system with belt conveyor

- Dryer for the pharmaceutical industry

- Cleaning dewatering system

- Stainless steel drying system

- Fluidized bed dryer

- Concentrator

- Horizontal drying system

- High-performance dryer

- Drying system with temperature control

- Drying system with automatic controls

- Plastic dewatering system

- Laboratory drying system

- Quick-drying dryer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.