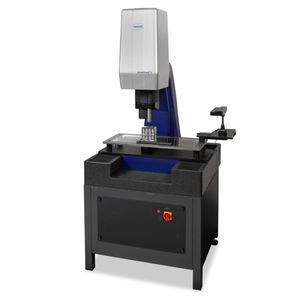

Gooseneck coordinate measuring machine StentCheck®multi-sensorhigh-precisioncompact

Add to favorites

Compare this product

Characteristics

- Structure

- gooseneck

- Probe type

- multi-sensor

- Other characteristics

- high-precision, compact, automated

- X travel

300 mm, 400 mm

(11.81 in, 15.75 in)- Y travel

200 mm

(7.87 in)- Z travel

200 mm

(7.87 in)

Description

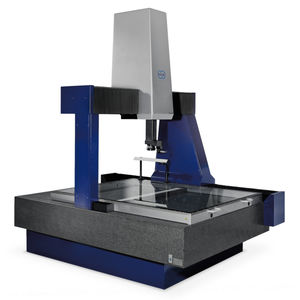

Life-saving stents – Tested quality with Werth multi-sensor coordinate metrology

The special configuration of the optical-tactile 3D coordinate measuring machine with special illumination unit and rotary/tilt axis enables highly accurate and fast complete measurement of stents. With the help of the rotary axis, special recording mandrels and the patented Raster Scanning HD ROTARY function, the cylinder jacket surfaces are scanned in sections or completely with the image processing sensor during rotation and made available for evaluation as a 2D image or 3D data record in the shortest possible time.

• Micrometre-precise and fully automatic optical measurement of hundreds of geometrical characteristics such as strut widths, radii and angles in a few tens of seconds

• Automatic evaluation with regard to defective structures with the powerful image processing system

• Special software tools prevent faulty measurements, such as those caused by webs that deviate greatly from the target geometry or by contamination

• The tilt axis extends the range of application to the measurement of conical and other non-cylindrical geometries, such as heart valve stents

• Thanks to the 3D measurement, spatial geometry elements can be captured (e.g. flare angle)

• The multi-sensor concept and the WinWerth® 3D measurement software enable tactile measurements, for example to determine the strut width, exactly at the positions of the stent previously determined with image processing

Accuracy

Permissible length measurement error up to 1.5 µm

VIDEO

Catalogs

No catalogs are available for this product.

See all of WERTH MESSTECHNIK‘s catalogsRelated Searches

- Measuring machine

- Optical measuring machine

- Automatic measuring machine

- Laser scanner

- Measurement scanning system

- High-precision measuring machine

- Touch probe head

- Measuring system for industrial applications

- Parts measuring machine

- Distance measuring machine

- Measurement touch probe head

- Inspection scanning system

- CMM

- Laser measurement system

- Video measuring machine

- 2D scanning system

- High-speed scanning system

- Dimensional measuring machine

- Length measuring machine

- 3D measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.