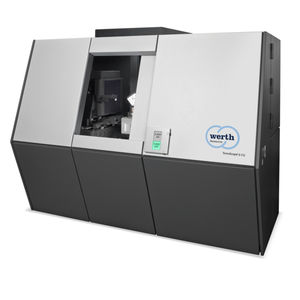

Large part coordinate measuring machine TomoScope® Sfor gearsfor lensesmulti-sensor

Add to favorites

Compare this product

Characteristics

- Applications

- for large parts, for gears, for lenses

- Probe type

- multi-sensor

- Other characteristics

- high-precision, compact, with computed tomography, with digital X-ray tomography

Description

High performance with compact external dimensions are the designation of the Werth TomoScope® S. The available X-ray tubes with transmission target offer a very small focal spot even at high tube power and thus highest resolution at high measuring speed. X-ray detectors with a large number of pixels and detector area ensure the highest resolutions with a large measuring range at the same time. Areas of application are workpieces with high density (aluminum, steel, titanium, elastomers, hybrid plastics, ceramics, multi-materials (e.g. connectors), assemblies, glass fibre reinforced plastics).

• Optical workpiece positioning aid for easy positioning of the measuring objects

• Due to the accuracies achievable with the patented subvoxeling method and the high density of measuring points, this technology is also ideally suited for the correction of tools for injection moulding

• The design and construction of all TomoScope® machines correspond to full protection devices according to the Radiation Protection Ordinance

• A workpiece changing system can be integrated into the machine housing and the computed tomography coordinate measuring machine can also be used continuously and automatically overnight and at weekends

• Highly accurate 3D measurements, even in production or incoming goods, thanks to optional active unit air-conditioning

• Standard-compliant calibration according to VDI 2617 for reliable and traceable measurement results, optionally with DAkkS certificate

Measuring range

Max. Workpiece dimensions D = 204 mm / L = 398 mm (depending on the aspect ratio of the workpieces)

Accuracy

Permissible length measurement error up to 4.5 µm

VIDEO

Catalogs

No catalogs are available for this product.

See all of WERTH MESSTECHNIK‘s catalogsRelated Searches

- Measuring machine

- Optical measuring machine

- Automatic measuring machine

- Measurement scanning system

- Laser scanner

- High-precision measuring machine

- Touch probe head

- Measuring system for industrial applications

- Parts measuring machine

- Distance measuring machine

- Measurement touch probe head

- Inspection scanning system

- CMM

- Video measuring machine

- Laser measurement system

- 2D scanning system

- High-speed scanning system

- Dimensional measuring machine

- 3D measuring machine

- Length measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.