- Products

- Catalogs

- News & Trends

- Exhibitions

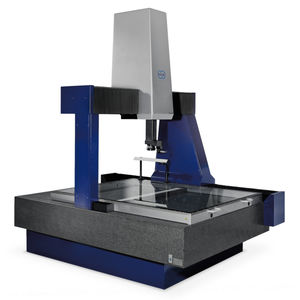

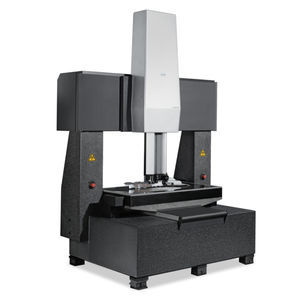

Gooseneck coordinate measuring machine ScopeCheck® Sfor gearsfor lensesmulti-sensor

Add to favorites

Compare this product

Characteristics

- Structure

- gooseneck

- Applications

- for gears, for lenses

- Probe type

- multi-sensor, optical

- Other characteristics

- compact, tabletop

- X travel

300 mm, 400 mm

(11.81 in, 15.75 in)- Y travel

200 mm

(7.87 in)- Z travel

200 mm

(7.87 in)

Description

The compact ScopeCheck® S features an extremely robust granite and polymer concrete construction with protected guideways and scales, as well as temperature compensation, making it optimised for use in production environments. The Werth image processing sensor included in the basic equipment is specially tailored to the needs of dimensional metrology and provides reliable edge detection even in the most difficult contrast conditions. Different focus variation methods enable optical 3D measurements. Typical areas of application are turned, milled, plastic, punched and bent parts.

• Integrated motor zoom optics 0.9x to 4.3x and interchangeable optics 1x to 100x, resp

• Increased flexibility through integration of additional sensors, rotary or rotary/tilt axes

• Contour image processing for automatic measurement of regular and free-form geometries in reflected and transmitted light

• Length measurement and probing errors specified according to ISO 10360

Accuracy

Permissible length measurement error up to 1.5 µm

VIDEO

Catalogs

The Multisensor_2015

20 Pages

Related Searches

- Measuring machine

- Optical measuring machine

- Automatic measuring machine

- Laser scanning system

- Measurement scanning system

- High-precision measuring machine

- Touch probe head

- Measuring system for industrial applications

- Parts measuring machine

- Distance measuring machine

- Measurement touch probe head

- CMM

- Video measuring machine

- Laser measurement system

- Inspection scanning system

- 2D scanning system

- High-speed scanning system

- Dimensional measuring machine

- 3D measuring machine

- Length measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.