- Products

- Catalogs

- News & Trends

- Exhibitions

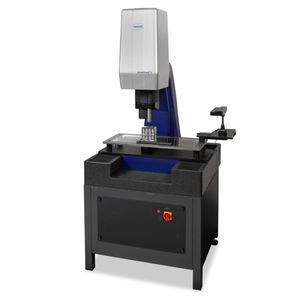

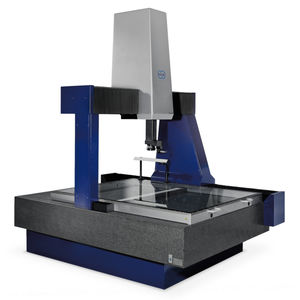

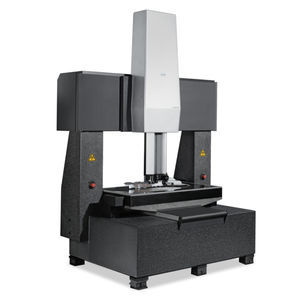

Bridge coordinate measuring machine ScopeCheck® FB gantryfor gearsfor crankshafts

Add to favorites

Compare this product

Characteristics

- Structure

- bridge, gantry

- Applications

- for gears, for crankshafts, for lenses

- Probe type

- multi-sensor, optical

- Other characteristics

- high-precision, compact

- X travel

Min.: 400 mm

(15.75 in)Max.: 2,000 mm

(78.74 in)- Y travel

Min.: 500 mm

(19.69 in)Max.: 1,000 mm

(39.37 in)- Z travel

Min.: 350 mm

(13.78 in)Max.: 1,000 mm

(39.37 in)

Description

Rigid design with fixed bridge for economical production monitoring with low measurement uncertainties

Perfectly integrated multi-sensor systems for shopfloor and measuring room

The machine series perfectly combines the benefits of conventional tactile and optical coordinate measuring machines. The granite-base design with fixed bridge enables excellent specifications with the highest measuring dynamics. The ScopeCheck® FB offers the optimum combination of precision and measuring range and has compact installation dimensions and a low weight.

With the proven multi-ram concept, multi-sensor measurements are possible without restriction. Up to three independent sensor axes (rams) allow quick sensor changes and minimise the risk of collision.

• The workpiece is easily accessible from all sides and the measuring range is not restricted by inactive sensors

• Heavy workpieces can be positioned and measured directly on the measuring table according to disassembly of glass table and transmitted light unit

• Ideal for use close to production thanks to robust mechanical precision guides instead of air bearings

• Measure optically with flexibility and accuracy thanks to integrated zoom optics

• Slim stylus quill enables collision-free measurement of geometries deep in the workpiece

• Second and third sensor axes can be retrofitted at a later date

VIDEO

Catalogs

No catalogs are available for this product.

See all of WERTH MESSTECHNIK‘s catalogsRelated Searches

- Measuring machine

- Optical measuring machine

- Automatic measuring machine

- Laser scanning system

- Measurement scanning system

- High-precision measuring machine

- Touch probe head

- Measuring system for industrial applications

- Parts measuring machine

- Distance measuring machine

- Measurement touch probe head

- CMM

- Laser measurement system

- Video measuring machine

- Inspection scanning system

- 2D scanning system

- High-speed scanning system

- Dimensional measuring machine

- 3D measuring machine

- Length measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.