- Industrial machines and equipment

- Mixing and Dosing

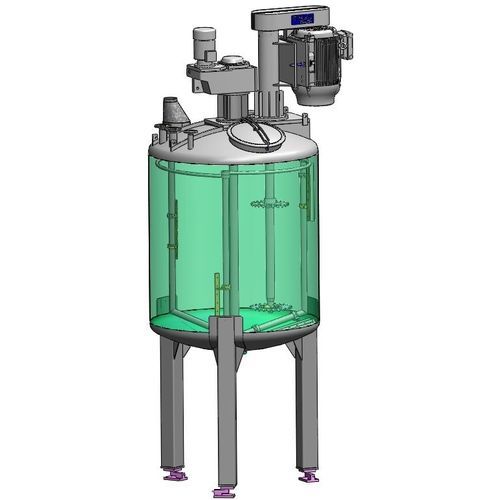

- Turbine mixer

- Westerlins Maskinfabrik AB

Turbine mixer WP-02batchfor liquidsvertical

Add to favorites

Compare this product

Characteristics

- Technology

- turbine

- Batch/continuous

- batch

- Product type

- for liquids

- Configuration

- vertical

- Other characteristics

- automatic, 3-shaft, disperser, ATEX

- Applications

- for the chemical industry, for the pharmaceutical industry, for the cosmetics industry, for the plastics industry, coating technology, for high-viscosity materials

Description

Wisperser type WP-02 is the Westerlins trade name for a series of highly efficient dispersers/mixers fitted with a minimum of two mixing devices, one being a high speed impeller disc and the other being a ‘mass mover’ type blade incorporating

a side and bottom scraper. The mixing process occurs in an entirely closed environment. The Wisperser is designed to suit all dispersing requirements from simple water based paint to tixotropic paste like products. All Wispersers have in common a bottom discharge hole which is asymmetric in order to achieve a faster discharge. Wispersers are manufactured with frequency inverter as standard for the Dissolver unit.

Options

The Wisperser can be adapted to suit the customer’s production philosophy with regards to charge sizes, local conditions, power requirements or corrosive products. The Wisperser can be equipped with an automatic power control (WPC), controlling both impeller speed and level in accordance with production requirements. The control panel can be fitted with additional instrumentation extra to our standard fittings.

High viscosity dissolver – Wisperser 1,0 to 20,0 m3 – Dispersion of highly viscous products:

Using a dissolver for dispersion is only possible with free-flowing substances, as only then can the mass be put into rolling, turbulence-free movement – the so-called ”doughnut effect”.

However, this effect is not achieved completely in the case of highly viscous, non free-flowing sub-stances.

The substance then remains almost immobile in the vessel during the dispersion process, it is not ”roll and the dissolver disc cannot apply any additional energy, with the result that it effectively runs free.

Catalogs

No catalogs are available for this product.

See all of Westerlins Maskinfabrik AB‘s catalogsRelated Searches

- Dynamic homogenizer

- Batch homogenizer

- Grinding mill

- Liquid agitator

- Vertical agitator

- Agitator for the chemical industry

- Horizontal grinding mill

- Agitator for the pharmaceutical industry

- Turbine agitator

- Paddle blender

- Homogenizer for the cosmetics industry

- Automatic homogenizer

- Laboratory homogenizer

- Explosion-proof agitator

- Blender for the plastics industry

- Disperser homogenizer

- ATEX agitator

- Laboratory grinding mill

- Single-shaft blender

- Ball grinding mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.