- Robotics - Automation - Industrial IT

- Industrial Software

- Control software

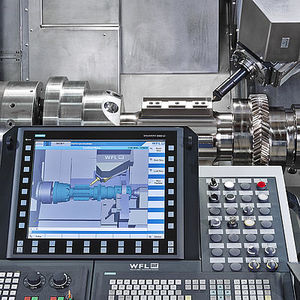

- WFL Millturn Technologies

- Products

- Catalogs

- News & Trends

- Exhibitions

Programming software FLANX I CRANXcontrolconfigurationfor CNC machines

Add to favorites

Compare this product

Characteristics

- Function

- programming, control, configuration

- Applications

- for CNC machines

- Type

- 3D

Description

The technology cycles of WFL cover an extremely broad range of standard and special technologies for all conceivable cases of application. These program modules, which only require the input of parameters, make it possible to carry out efficient programming directly on the machine control or on a PC. The program can therefore be created for both complex and simple workpieces within the shortest period of time.

The technology cycles of WFL simplify the programming considerably and are a direct route to achieving the desired production result. The wide range of technology solutions fulfils all machining requirements.

CRANX

Cycle packages for crankshaft machining, for complex multi-axis machining with feed out tools or for a workpiece finish using grinding clearly show: due to a needs-based cycle configuration, branch-specific requirements are handled quickly and efficiently.

Cycle selection

Utronix (virtual U-axis)

Cranx-Basic (basic crankshaft package)

Cranx-Advanced (extended crankshaft package)

Cranx-Plus (complete crankshaft package)

Function package for rotating feed out tools (tools for U-axis)

Related Searches

- Automation software solution

- Process software solution

- Computer-aided design software

- Control software solution

- Real-time software solution

- 3D software solution

- Industrial software solution

- Simulation software

- Programming software

- Data acquisition software

- CAM software

- Diagnostic software

- CNC machine software

- CNC control software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.