- Machine-tools

- Machining Center

- CNC milling-turning center

- WFL Millturn Technologies

- Products

- Catalogs

- News & Trends

- Exhibitions

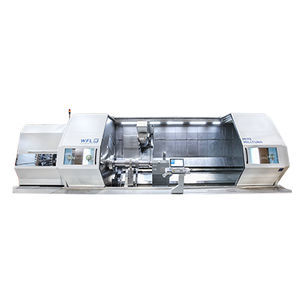

CNC milling-turning center 40X serieshorizontal4-axisspindle

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Type

- horizontal

- Number of axes

- 4-axis

- Structure

- spindle

- Other characteristics

- drilling

- Diameter

520 mm

(20.47 in)- X travel

800 mm

(31.5 in)- Y travel

400 mm

(15.75 in)

Description

With the M40, M40-G, M40X and M40X-G MILLTURN series, WFL Millturn Technologies is presenting a new generation of multifunctional turning-boring-milling centres for one-hit machining of complex chuck and shaft parts up to 520 mm swing over bed. Beside superior output and torque values of the spindle drives, the imposing feed forces in all axes make for superb dynamics and maximum productivity.

Highlights at a glance

Wide distances between guideways for the stable accommodation of big steady rests

Pick-up magazine for long tools with standard tool interface

B-axis turning

Workpiece transfer

High-precision measuring with integrated measuring probe

The standard tool interface

High coolant pressure

High coolant pressure for optimised chip breakage

Coolant pressure below 150 bar – High Pressure Coolant (HPC)

Coolant pressure between 150 and 350 bar – Ultra-High Pressure Coolant (UHPC)

Significant increases in cutting parameters, tool life and process safety

Reduced machining costs

No additional interfaces required for up to 200 bar (coolant supplied directly through the milling spindle)

Coolant solutions for deep hole drilling

High coolant supply rates to ensure the best possible removal of chips from the hole – this makes the MILLTURN a fully-fledged deep hole drilling machine

Coolant supply rates of up to 200 l/min

External interfaces with manual docking

Individual configuration of the coolant pumps and filters

Special tool heads

Special tool heads for special manufacturing requirements (difficult to access workpiece geometries, special processes and special coolant solutions)

Related Searches

- Turning-milling machine

- CNC turning-milling center

- Horizontal turning-milling center

- Spindle turning-milling center

- 3-axis turning-milling center

- 5-axis milling-turning machine

- High-precision turning-milling center

- Turning-milling center with turret

- Compact turning-milling center

- Milling-turning center for the automobile industry

- High-productivity milling-turning center

- Cutting turning-milling center

- Drilling turning-milling center

- High-speed milling-turning center

- Modular milling-turning center

- High-power milling-turning center

- 4-axis milling-turning center

- Deep hole milling-turning center

- Inclined bed milling-turning center

- Large milling-turning center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.