- Machine-tools

- Machining Center

- CNC milling-turning center

- WFL Millturn Technologies

- Products

- Catalogs

- News & Trends

- Exhibitions

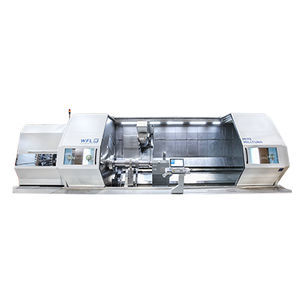

CNC milling-turning center M200horizontal3-axisfor large parts

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Type

- horizontal

- Number of axes

- 3-axis

- Other characteristics

- for large parts, for automatic tool changers, for the aeronautical industry

- Diameter

2,000 mm

(78.74 in)- X travel

2,100 mm

(82.68 in)- Y travel

1,400 mm

(55.12 in)

Description

Designed by the Austrian high tech company WFL Millturn Technologies, the M200 MILLTURN is a first-class multifunctional turning-boring-milling center. Complete machining enters a whole new dimension with this revolutionary machine-tool generation.

Established MILLTURN-assemblies were combined with a new machine bed concept in order to create an uncompromising turning-boring-milling center for complete machining of large work pieces. Different headstock and tailstock versions cover operations ranging from the production of aerospace components with large swing diameters to the production of large and heavy chuck or shaft parts.

Highlights auf einen Blick

UHPC with up to 350 bar

Standard disc-type magazine with up to 90 tool stations

Heavy boring bar magazine

Tool magazine

Tool change

Generously dimensioned and automated tool changer with double gripper

Time-saving due to a highly dynamic changing sequence

Reliable changing sequences, also with heavy tool weights

Tool change of tools measuring up to 1000 mm and 40 kg possible

Tool magazine

Standard disc-type magazine with up to 90 tool stations

Optional chain magazine for operations involving a high number of tools

Optional magazine version for particularly long and heavy tools (e.g. heavy boring bars)

Optimum user-friendliness of all magazine versions

Related Searches

- Turning-milling machine

- CNC turning-milling center

- Horizontal turning-milling center

- Spindle turning-milling center

- 3-axis turning-milling center

- 5-axis milling-turning machine

- High-precision turning-milling center

- Turning-milling center with turret

- Compact turning-milling center

- Milling-turning center for the automobile industry

- High-productivity milling-turning center

- Cutting turning-milling center

- Drilling turning-milling center

- High-speed milling-turning center

- Modular milling-turning center

- High-power milling-turning center

- 4-axis milling-turning center

- Deep hole milling-turning center

- Inclined bed milling-turning center

- Large milling-turning center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.