- Machine-tools

- Machining Center

- CNC milling-turning center

- WFL Millturn Technologies

- Products

- Catalogs

- News & Trends

- Exhibitions

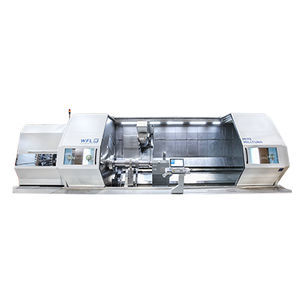

CNC milling-turning center M150horizontal5-axisspindle

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Type

- horizontal

- Number of axes

- 5-axis

- Structure

- spindle

- Other characteristics

- drilling, cutting, for automatic tool changers

- Diameter

Min.: 1,360 mm

(53.54 in)Max.: 1,560 mm

(61.42 in)- X travel

1,120 mm, 1,150 mm

(44.09 in, 45.28 in)- Y travel

800 mm

(31.5 in)

Description

With the models M100, M120 and M150 WFL Millturn Technologies is presenting the absolute champions of multifunctional turning-boring-andmilling centers, allowing one-hit machining of complex workpieces of up to 8m* length. Besides superior output and torque values of the spindle drives, the imposing feed forces in all axes make for superb dynamics and maximum productivity.

Turning, milling, boring, gear cutting, gun drilling as well as ID machining can be performed under any angle of the tool. The interpolation of up to five axes makes machining of any geometrical profile possible. The sturdy, single piece 60° slant bed made of grey cast iron and the use of generously dimensioned guideways with extra-wide size ensure perfect stability and optimum antivibration behaviour. The incomparable number of hardware and software options plus the meticulously designed machine structure are the consequence of many years at the edge of technology.

Highlights at a glance

Ergonomically designed workspace

In-process measuring

Chuck mounted on right side

The prismatic interface

A second tool interface takes care of those tools that exceed the maximum dimensions of the standard equipment. Thanks to the particularly stable prismatic accommodation, boring bars, solid drills, angular heads and facing heads can be securely fixed onto the milling unit. The use of the special WFL system boring bar opens up the possibility of automatically changing the cutting heads too. For the automatic handling of heavy ID-machining tools, two different magazine types are available.

Related Searches

- Turning-milling machine

- CNC turning-milling center

- Horizontal turning-milling center

- Spindle turning-milling center

- 3-axis turning-milling center

- 5-axis milling-turning machine

- High-precision turning-milling center

- Turning-milling center with turret

- Compact turning-milling center

- Milling-turning center for the automobile industry

- High-productivity milling-turning center

- Cutting turning-milling center

- Drilling turning-milling center

- High-speed milling-turning center

- Modular milling-turning center

- High-power milling-turning center

- 4-axis milling-turning center

- Deep hole milling-turning center

- Inclined bed milling-turning center

- Large milling-turning center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.