- Machine-tools

- Machining Center

- CNC milling-turning center

- WFL Millturn Technologies

- Products

- Catalogs

- News & Trends

- Exhibitions

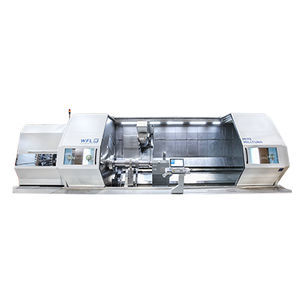

CNC milling-turning center M65horizontal3-axishigh-precision

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Type

- horizontal

- Number of axes

- 3-axis

- Other characteristics

- high-precision, drilling, cutting, deep hole

- Diameter

760 mm, 830 mm

(29.92 in, 32.68 in)- X travel

720 mm

(28.35 in)- Y travel

600 mm

(23.62 in)

Description

Anyone who wishes to stay ahead in the market must react quickly and in a flexible manner to their customers’ requirements. The components that customers require are becoming increasingly complex and therefore more demanding to manufacture. By combining all of the manufacturing steps in a multifunctional MILLTURN turning-boring-milling centre, the requirements of both current and future manufacturing jobs can be fulfilled with the highest level of precision. The possibility of freely interpolating the NC axes B, C, X, Y and Z offers the user an incomparable range of technologies. Complete machining without manual intervention, by means of turning, drilling, milling, deep hole drilling, internal and external gear cutting, turn-milling, circular milling and automatic workpiece measurement to enable compliance with the tightest of tolerances. Compensation of thermal influences is also provided for. Any geometric profile can be efficiently machined with the maximum level of precision. There are absolutely no limits when it comes to workpiece complexity.

Its multifunctionality is simply ingenious.

Highlights at a glance

Individual clamping solutions

Automatic coolant docking

Turning-boring-milling unit with integrated measuring probe

Workpiece transfer

Related Searches

- Turning-milling machine

- CNC turning-milling center

- Horizontal turning-milling center

- Spindle turning-milling center

- 3-axis turning-milling center

- 5-axis milling-turning machine

- High-precision turning-milling center

- Turning-milling center with turret

- Compact turning-milling center

- Milling-turning center for the automobile industry

- High-productivity milling-turning center

- Drilling turning-milling center

- Cutting turning-milling center

- High-speed milling-turning center

- Modular milling-turning center

- High-power milling-turning center

- 4-axis milling-turning center

- Deep hole milling-turning center

- Inclined bed milling-turning center

- Large part milling-turning center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.