White Mountain Process offers disposable and single-use mixing, shaking, and blending technology for biopharma and high purity manufacturers. We cater to OEMs who are integrating mixers into their own single use process systems, and to end users who want customized single-use mixing designed to their specifications and requirements. Our offerings include:

• Mixer and agitator drives with various output speeds and motor configurations

• Variety of “wetted” materials available

• Including 316Lss, USP VI PE/PP/PVDF, Hast C, Titanium, and other exotic materials

• Variety of mixer connections for open containers and closed/sealed bags

• Custom designs for any single use mixing application

• Lab mixing to pilot scale blending to full scale agitation

Single-Use Mixer Features

FOR DISPOSABLE MIXING WITH ASEPTIC SEALED DISPOSABLE MIXER & CONTAINER

• Single use top entry mixer drive blending system

• Sealed sterile containers

• Disposable mixer and container setup

• Gamma radiated / sterilized mixing bags

• Full cert package

• Bottom entry mixing systems with NO moving parts (zero shedding, no particulate generation, eliminate CIP/SIP, no cross contamination between batches – White Mountain Process loves single use mixing)

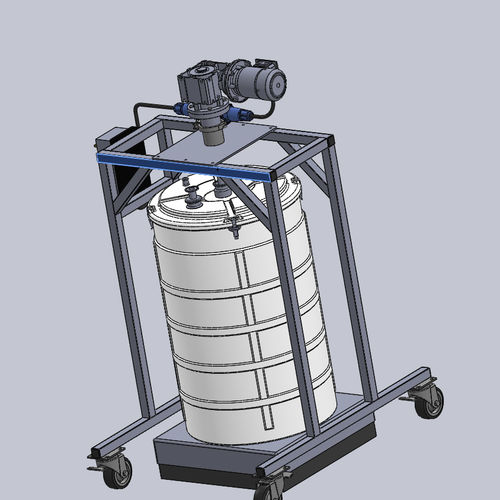

Sanitary C-Clamp Mixer on Poly portable push cart, used for mixing multiple sized carboys with single use disposable bag liners. Mixer has quick disconnect “tool-less” arrangement to easily remove shaft/impeller assembly. Disposable poly USP VI PP mixing impeller and shafts are also available. Poly carts and tanks are built to client specifications.