- Machine-tools

- Cutting Tool

- External turning tool

- Whizcut of Sweden AB

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

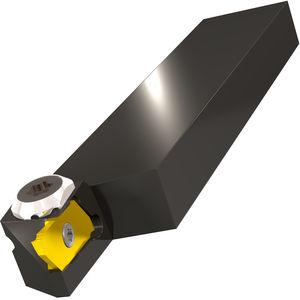

External turning tool WhizHipinsertwith internal coolantSwiss type lathe

Add to favorites

Compare this product

Characteristics

- Type

- external

- Features

- insert

- Other characteristics

- with internal coolant, Swiss type lathe

Description

WhizHip is a series of tool holders with high pressure coolant for Swiss type lathes / sliding heads. The high pressure coolant is lead through the tool holder and exits at an optimal angle between the cutting edge and chip to cool the insert and to cut off the building chips. Most tool holders use standard ⅛ NPT connection to connect the coolant from the machine. By using the WhizHip tool holders, an investment in a special gang-plate is not needed.

To minimize setup time we recommend you to use the WhizFix tool holder option of the WhizHip. This way you will not need to take out the tool holder out of the machine when indexing the insert.

he optimal coolant point is between the chip and the cutting edge which gives improved cooling effect, improved chip control and improved tool life. The best coolant pressure varies between machine, material, RPM and feed rate. The WhizHip tool holder gives a positive effect on performance already from 10 bar. Normal use is around 75 bar, however up to 200 bar can be used.

When working in titanium, and other difficult to machine materials one will find a drastically improved performance of the insert when using high pressure coolant.

Catalogs

WhizCut 2013

56 Pages

Whizcut 2019

37 Pages

Related Searches

- Milling tool

- Solid milling tool

- Drilling tool

- Clamping milling cutter

- Solid drilling tool

- Milling tool with cylindrical shank

- Coated milling cutter

- General purpose drill bit

- Hemispherical milling cutter

- Solid carbide milling tool

- Carbide drilling tool

- Turning tool

- Insert turning tool

- Turning insert

- Thread milling tool

- Mini milling cutter

- Angle milling cutter

- Grooving tool

- External turning tool

- Micro milling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.