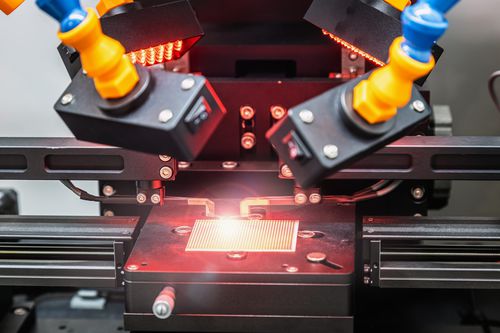

Laser micro-machining pairs a nanosecond, picosecond, or femtosecond laser with a high-speed and high-accuracy scanner assembly that moves to beam at a speedy rate. Most scanner assemblies are 2 or 3-axis, however, some applications require more advanced options such as a 5-axis or polygon scanner.

Ablation uses a 2 or 3 or 5-axis scanner to remove precise layers of material.

Typically used for texturing, coating removal, or aerospace diffusers.

Using galvo mirrors and programmed toolpaths to achieve fast material removal of metallic and non-metallic materials.

Automation ready – Overhead or front loading with minimal operator intervention for lights-out operation. Paint-to-paint or transfer line configurations are available.

A range of laser sources paired with scanner assemblies is available to suit the applications and material. Laser sources are available from microsecond down to femtosecond pulse widths.