- Industrial machines and equipment

- Welding and Assembly

- Butt welding machine

- WINCOO ENGINEERING LTD

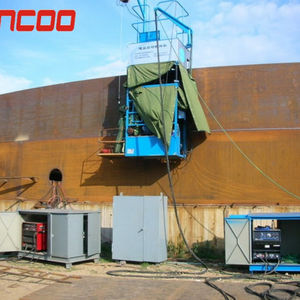

Butt welding machine MLTW-P/J automaticfor storage tanks

Add to favorites

Compare this product

Characteristics

- Technique

- butt

- Operational mode

- automatic

- Applications

- for storage tanks

- Power

25,000 W

Description

Product introduction

Master Frame

1. Master frame of the girth welder is constructed of structural steel and square tube members.

2. Erection Method: Bottom-to-Top

3. Min Diameter: Φ5.0m

4. Shell Width: Bottom-to-top 1.5-3.0m

Dual Motor Drive

1. The dual AC motor design allows for constant travel across the entire tank circumference. When fit up is not quite perfect or there is an uneven surface for the machine to travel, the dual motors will power the machine across the imperfection. This design will reduce the amount of time required to repair weld defects and will decrease the overall tank erection costs. The dual motors are controlled by one easily

2. Programmable frequency inverter.

Power Source and Wire Feeder

1. The welding equipment supplied is the Miller HDC1500DX control and RAD400 weld head fitted with nozzle and wire rolls. Wire reel(27.2kg)will be supplied with equipment too.

2. Power source : SubArc DC800,CE

3. HDC1500DX Welding Progress Control

4. RAD400 Wire Feeder

Model - MLTW-P/J

Manufacturer - WINCOO

Factory Location - South of Times Avenue, Liuhe Economic Development Zone, Nanjing City(211507),Jiangsu Province, P. R. China

Welding Currency - 100-1250A

Welding Voltage - 20-45V

Welding Speed - 200-650mm/min

Power Input - 380/3PH/50Hz

Rated power - 25kw

Groove - Square groove/Single V groove /Lap joint

Position - Flat/Fillet weld

Full traveling speed - 1000mm/min

Tank Dia - 5.0m and above

Wire Dia - Φ2.4mm-Φ4.8mm

Torch adjustment - 3 axis

Torch up/down adjustment - ±25mm

Torch fwd/rev adjustment - ±25mm

Capacity of flux container - 10Kg

Welding Process - SAW

Plate sickness - 6mm and above

Catalogs

No catalogs are available for this product.

See all of WINCOO ENGINEERING LTD‘s catalogsRelated Searches

- Welding system

- Automatic welding system

- Arc welding system

- Precision welding system

- Plastic welding system

- Resistance welding system

- Mounting machine

- Butt welding machine

- PLC-controlled welding system

- Automatic mounting machine

- Hydraulic welding machine

- High-precision welding system

- Plastic pipe sealer

- Pipe welding system

- Vertical welding system

- Welding rotator

- Orbital welding machine

- Heavy-duty welding system

- Storage tank welding machine

- Electrofusion welding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.