- Production Machines

- Cutting Machine

- Flame cutting machine

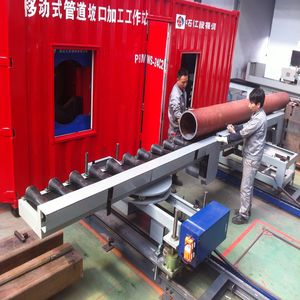

- WINCOO ENGINEERING LTD

Flame cutting machine BPFBM seriesplasmafor steeltube

Add to favorites

Compare this product

Characteristics

- Technology

- flame, plasma

- Material

- for steel

- Product handled

- tube

- Control type

- CNC

- Associated function

- profiling, beveling

- Tube diameter

Max.: 600 mm

(24 in)Min.: 100 mm

(4 in)

Description

1. Model: BPFBM-24A2 /32A2/48A2

2. Performance features

· On-line Performance: very good (Designed as per the on line equipment of the production line)

· Beveling Speed: ≤3Min /pipe bevel (DN200 SCH40) /≤5Min /two pipe bevels (DN200 SCH40)

· Bevel cutting: cutting off & with one bevel of the pipe at simultaneously for /cutting off & with two bevels of the pipe at simultaneously

· Bevel quality: good

3. Technical parameters

· Pipe diameter applicable: DN100~600(φ114~610)

· Applicable wall thickness: 5~50 mm

· Materials applicable: carbon steel, alloy steel, and cryogenic steel

· Cutting length: 6350MM

· Bevel Shape: V

· Cutting direction: lengthwise

· Roller bench:

Structure: Three line steel roller with fixed distance

Roller Bench Length:7000MM

Driving System: servo motor + precision reducer

Rev: 0~2.5M/Min (VF stepless speed adjustment)

Roller bench Material:45#, Surface bluing treatment

Rotation Accuracy:<2.0MM

· Trolley System:

Trolley travel: 6350MM(moving lengthwise)

Cutting torch travel: 700MM (up/down); 300MM (in/out)

Cutting with: flame cutting(can be equiped with plasma cutting)

Cutting Torch Angle:±45°(adjustable)

Cutting Torch Quantity: one piece of flame cutting torch /three pieces of flame cutting torch

Angle error: <2°

Length fixing accuracy:<2.0MM

· Control System: SH-2000H Flame CNC Cutting System

· Length-measuring system: CNC length measuring which is included in the control system.

Conveying system: built in a conveying system equipped with a lifter; one set of conveying system can be provided additionally for bevel cutting machine if necessary and conveying can be implemented manually or electrically.

Catalogs

No catalogs are available for this product.

See all of WINCOO ENGINEERING LTD‘s catalogsOther WINCOO ENGINEERING LTD products

Pipe spool fabrication line

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Metal sawing machine

- High-precision cutting system

- Automatic sawing machine

- Tube cut-off machine

- Band sawing machine

- Steel cutting system

- Tube saw

- Plasma cutting system

- Steel sawing machine

- Cutting machine with servo-motor

- Beveling cutting machine

- Steel construction cutting machine

- Shipbuilding cutting system

- Shipyard cutting machine

- Oxyacetylene cutting machine

- High-speed sawing machine

- Profiling cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.