- Production Machines

- Other Manufacturing Equipment

- Paper bag making machine

- WINDMÖLLER & HÖLSCHER

- Products

- Catalogs

- News & Trends

- Exhibitions

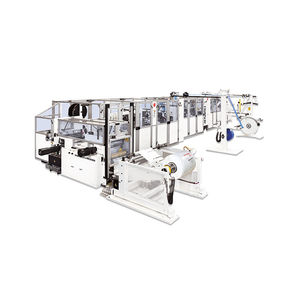

Paper bag making machine AD 8320automatic

Add to favorites

Compare this product

Characteristics

- Material

- paper

- Other caracteristics

- automatic

- Width

Max.: 60 cm

(23.62 in)Min.: 18 cm

(7.09 in)

Description

Your bottomer for universal sacks and easy set-up

up to 330 sacks / min

CNC

reduced set-up times

flexibility in sack and valve designs

paper valve sacks

agricultural

food

industrial

AD 8320 is the highly efficient and flexible multi-purpose valve bottomer for small and medium size bags. It is the first bottomer in the world to produce sacks with filling volumes down to 2 litres and specially suited to short run production with frequent size changeovers.

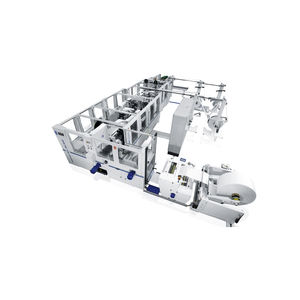

In conjunction with a W&H tuber, the automated material flow systems TRANSYSTEMS, TRANSIFLEX or TRANS-TOWER and the ARCOMAT robot palletiser or, alternatively, the ROTASAC bag-on-a-roll winder, the AD 8320 bottomer represents a highly efficient in-line system for the fully automatic production of multiwall paper sacks.

Sack length - 25 – 118 cm

Bottom width - 7 – 18 cm

Bottom center distance - 18 – 100 cm

Sack volume - 2 – 100 litres

Product speed - max. 330 sacks/min

Catalogs

Product Range

44 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.