- Products

- Catalogs

- News & Trends

- Exhibitions

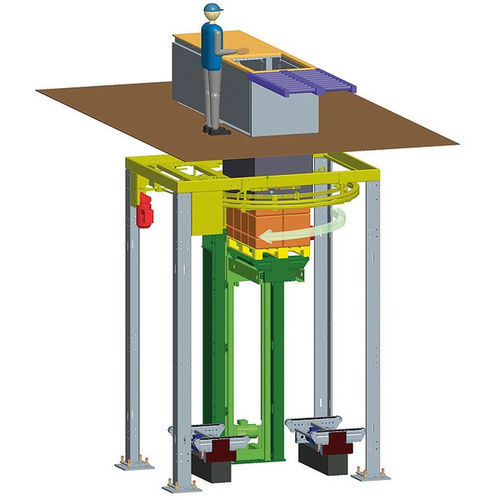

Work platform FAST PICKliftingloadingunloading

Add to favorites

Compare this product

Characteristics

- Function

- work, lifting, loading, unloading, order-picking

- Type

- roller

- Applications

- pallet

- Load limit

1,300 kg

(2,866 lb)

Description

The FAST PICK STATION can handle different carriers: euro pallets, ½-Euro pallets, industrial pallets, roller container, crates …

Efficient and ergonomic picking with high performance

Palletizing, (loading and unloading) and other material handling processes are typical tasks where goods are moved in the shortest time possible. Now, a WINKEL innovation combines high performance, efficient motion control and extreme reliability in the FAST PICK STATION.

What is the FAST PICK STATION?

The FAST PICK STATION consists of a work station that processes, shrink wraps, stacks and conveys pallet ready shipments quickly and efficiently. The goods are forwarded down through the shaft and shrink wrapped immediately,securing the goods for shipment.

The FAST PICK STATION can be easily integrated into existing conveying systems since it does not require a pit.

The FAST PICK STATION can be used with a number of applications, including unit conveying and package processing, e.g. automotive parts, food, textile, drug and other packaged goods.

Pallets with mixed goods can also be commissioned with the FAST PICK STATION without any problems.

Technical Datas FAST PICK STATION

-Load capacity: up to 1300 kg

-Stroke: 450 mm above floor - max 6000 mm

-Commissioning: up to 800 Pick-ups/hour

Advantages FAST PICK STATION

-up to 800 picks on pallets in 1 hour

-automatic loading safety

-shorter order processing time

-minimum space requirements

-flexible integration

FAST PICK STATION - Productfacts

-Innovative commissioning system for pallets

-manual or automatic commissioning on pallets

VIDEO

Catalogs

WINKEL Catalogue

420 Pages

EFFICIENT

5 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Lifting system

- Tipping station

- Working platform

- Column type lift system

- Mobile platform

- Lifting platform

- Hydraulic lifting system

- Steel fork

- Loading platform

- Metal lifting and turning device

- Telescopic fork

- Roller platform

- Pallet lift

- Unloading platform

- Telescopic arm lift system

- Lift mast

- Metal lifting and turning device with gripping tool

- Coil metal lifting and turning device

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.