- Production Machines

- Forming Machine

- Electric bending machine

- Winton Machine Company

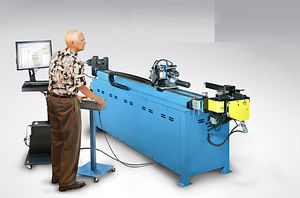

Electric bending machine RD20 eCNCtubeCNCautomatic

Add to favorites

Compare this product

Characteristics

- Operation

- electric

- Product handled

- tube

- Control

- CNC, automatic

- Number of axes

- 3-axis

Description

Product Description

The Winton RD20 eCNC tube and pipe bender is a PC controlled 3 axis CNC tube and pipe bender able to make mandrel bends. Built in the United States, this CNC tube bender is easy to operate. To get started, the operator programs the distance between bends, the plane rotation between bends and the bend angles. Then, after a tube is loaded, the operator presses a button and production begins. It’s that simple. All 3 axis of motion are closed-loop feedback for excellent repeatability. With the “Regrip” feature, the RD20 eCNC can be configured to make even the most difficult parts. This tube bender provides unlimited part program storage, limited only by free hard disk space.

The RD20 eCNC is very compact and capable of bending copper, aluminum and other metals. It has applications in the refrigeration, HVAC, automotive and many other industries.

To keep the programming of new bent tubular parts to a minimum, the tube bender can be linked direct to engineering. An optional Windows PC interface for programming the CNC tube bender can read in a CAD generated STEP file of a bent tube. That means you can go from a solid model to a bent tube in seconds. This helps cut down on programming time and data entry errors. Therefore, there is never a need to type into the controller the tube’s LRA or XYZ data points. The CNC tube bender’s controller can read a STEP file and extract the LRA (YBC) bend data, centerline radius, as well as the parts cut length. This saves programming time and makes your life easier. Tube bending should be easy.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Winton Machine Company‘s catalogsOther Winton Machine Company products

Tube Fabrication Machines

Related Searches

- Bender

- Tube bender

- Hydraulic bender

- Electric bender

- CNC bender

- Automatic bender

- Forming machine

- Manual bender

- Mandrel bender

- Metal forming machine

- Digitally-assisted bending machine

- Compact bender

- Handheld bender

- Hydraulic forming machine

- Pipe-end forming machine

- Servo-electric bending cell

- XYZ bending machine

- Forming bending machine

- Tube forming machine

- PLC-controlled forming machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.