- Production Machines

- Forming Machine

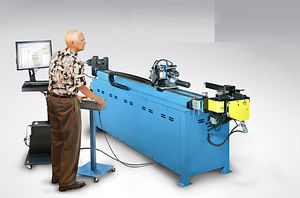

- Electric bending machine

- Winton Machine Company

Electric bending machine SB seriestubeCNCautomatic

Add to favorites

Compare this product

Characteristics

- Operation

- electric

- Product handled

- tube

- Control

- CNC, automatic

Description

Product Description

The SB series CNC serpentine tube benders are designed for high speed production use. All SB models tube benders provide for serpentine tube bending without the need to rotate the material between bends (R axis plane rotation).

Program the bend angles, centerline radius, straight lengths, and serpentine production begins. The tubing always stays in contact with the support table maintaining flatness. One of the advantages of the SB series type tube bender is its ability to manage the serpentine coil as it is being formed. Because the bend head can bend both CW and then CCW without rotating the tube between bends, the ability to control larger serpentine coils becomes much easier.

The serpentine bender bends CW and CCW without the need to rotate the tube between bends. This feature often becomes important to ensure the bent serpentine tubing remains flat. In heat transfer applications, a flat serpentine coil translates into an efficient product. A split die actuator comes standard and allows for tight radius bending. The design of the bend head allows for instant CW or CCW bending.

All SB serpentine tube benders come standard with a tube straightener and a payoff to support a bulk spook of tubing. An optional cutoff provides for fast and accurate cutting of the tube after the serpentine profile has been formed.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Winton Machine Company‘s catalogsOther Winton Machine Company products

Tube Fabrication Machines

Related Searches

- Bender

- Tube bender

- Hydraulic bender

- Electric bender

- CNC bender

- Automatic bender

- Forming machine

- Manual bender

- Mandrel bender

- Metal forming machine

- Digitally-assisted bending machine

- Compact bender

- Handheld bender

- Hydraulic forming machine

- Pipe-end forming machine

- Servo-electric bending cell

- XYZ bending machine

- Forming bending machine

- Tube forming machine

- PLC-controlled forming machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.