- Production Machines

- Cutting Machine

- Tube cutting machine

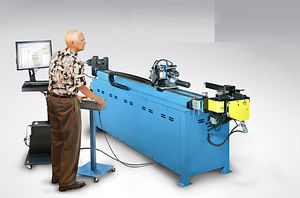

- Winton Machine Company

Tube cut-off machine CTL-30PAautomaticprogrammable

Add to favorites

Compare this product

Characteristics

- Product handled

- tube

- Other characteristics

- automatic, programmable

- Tube diameter

1 in

Description

Product Description

The CTL-30PA automatic tube cutter comes standard with programmable part quantity and programmable cut length. A material low indicator is used to sense the end of a straight length and alerts the user to load the next straight length for processing. The software doesn’t miss a beat, keeping track of the number of parts cut as new straight lengths are loaded into the machine.

Level wound spools of copper and aluminum can be processed with this tube cutting system. Thin wall stainless steel can be cut using this technique as well.

Automatic feed & cut...that is what the CTL-30PA tube processing system is designed to do.

The CTL-30PA is a free standing tube cutoff machine that automatically feeds and cuts from a bulk spool of tubing (level wound spool) or straight lengths. Designed for production, the CTL-30PA automatic tube cutter makes use of two backup rolls and (1) chipless type cutter to cut through small diameter tubing. With the tubing clamped, the backup rolls and cutter come in to make the cut. As the cutter continues to come in, the backup rolls plateau on the tube’s outside diameter thus providing excellent support during the chipless-cutting process.

Microprocessor controlled

Keypad & display for user input

Capacity: 1.188" OD copper tubing

Feed rate: 12" per second, maximum

Automatic pull-apart chipless type cut

Automatic unload

Electric Servo used to feed material forward

Multi-roll powered straightener, horizontal

Free standing machine with NEMA electrical box

5 speed settings for material feed rate

Programmable part cut lengths, inches/mm

Programmable number of parts to cut

Catalogs

No catalogs are available for this product.

See all of Winton Machine Company‘s catalogsOther Winton Machine Company products

Tube Fabrication Machines

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.