- Production Machines

- Forming Machine

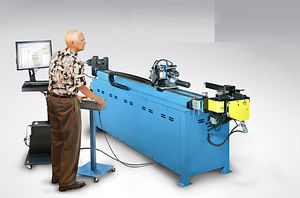

- Servo-electric bending machine

- Winton Machine Company

Servo-electric bending machine RD30LNtubeCNC3-axis

Add to favorites

Compare this product

Characteristics

- Operation

- servo-electric

- Product handled

- tube

- Control

- CNC

- Number of axes

- 3-axis

- Other characteristics

- draw

Description

Product Description

Winton Machine’s RD30L CNC tube bender makes use of one of the most compact bend heads in the industry yet at the same time provides for a long nose for bending tight configurations. The long nose (LN) bend head allows for bending of profiles that rotate below the bend tooling itself. In addition to the compact bend head design, the 3 axis servo controlled tube bender is fast and accurate. Controlled by a Windows-based computer, Winton’s RD30L tube bender has a history of standing the production test of time.

To keep programming of new parts down to a minimum, the RD30L tube bender can be linked directly to engineering. Engineering can download a CAD generated STEP file of a bent tube right into the tube bender’s controller. This helps cut down on programming time and programming errors. The controller reads the an industry standard STEP file and extracts the LRA (YBC) bender data. The LRA bender data is then used to control the CNC tube bending machine. It’s that simple.

The RD30L is mandrel tube bender and can be integrated with an automatic tube loader.

Winton Machine produces CNC tube benders ranging from 1mm to 50mm capacity. Give us a call. We would like to help you reduce your cost of goods sold.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Winton Machine Company‘s catalogsOther Winton Machine Company products

Tube Fabrication Machines

Related Searches

- Bender

- Tube bender

- Hydraulic bender

- Electric bender

- CNC bender

- Automatic bender

- Forming machine

- Manual bender

- Mandrel bender

- Metal forming machine

- Digitally-assisted bending machine

- Compact bender

- Handheld bender

- Hydraulic forming machine

- Pipe-end forming machine

- Servo-electric bending cell

- XYZ bending machine

- Forming bending machine

- Tube forming machine

- PLC-controlled forming machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.