- Production Machines

- Forming Machine

- Fully-electric bending machine

- Winton Machine Company

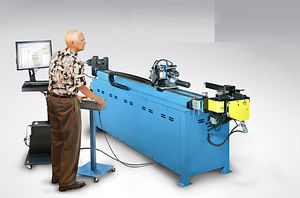

All-electric bending machine RD10tubeCNC3-axis

Add to favorites

Compare this product

Characteristics

- Operation

- all-electric

- Product handled

- tube

- Control

- CNC

- Number of axes

- 3-axis

- Other characteristics

- mandrel, draw

- Bending capacity

10 mm

(0.39 in)

Description

The RD10 CNC tube bender is built to bend small diameter tubing including brake lines, refrigeration components, and fuel lines. Production ready, this three-axis all-electric tube bender uses a Windows-based interface for operator control. The machine comes standard as a single radius CNC tube bender. An optional dual stack bend head allows a user to bend tubing using two different radii.

The RD10 bends stainless steel up to Ø10mm (3/8”) using a rotary draw process. This technique has proven to be effective for tight radius bending. The collet closer that holds the tubing during the bending process makes use of 80 PSI shop air. This ensures the tube is help tight before, during, and after a plane rotation. The design of the carriage spindle allows the end of the tubing to get right up next to the bend tooling on the very last bend. This often translates into avoiding a trimming operation after bending.

Software features include hitch feed, pause before bend, XYZ to LRA conversion, interference checking, 3 axis per bend speed settings, and more. An optional STEP file converter allows a user to read in a CAD generated STEP file direct from CAD right into the bender’s controller. No need to type in the tube’s bend data standing at the RD10, go ahead and read in the 3 dimensional bend data direct from your CAD system. It’s that simple.

The RD10 is a fast, accurate, and repeatable CNC tube bender. Designed and built in the US, this small diameter CNC bender is production ready. Give us a call with your application. We are motivated to help you reduce your cost of goods sold.

Catalogs

No catalogs are available for this product.

See all of Winton Machine Company‘s catalogsOther Winton Machine Company products

Tube Fabrication Machines

Related Searches

- Bender

- Tube bender

- Hydraulic bender

- Electric bender

- CNC bender

- Automatic bender

- Forming machine

- Manual bender

- Mandrel bender

- Metal forming machine

- Digitally-assisted bending machine

- Compact bender

- Handheld bender

- Hydraulic forming machine

- Pipe-end forming machine

- XYZ bending machine

- Servo-electric bending cell

- Forming bending machine

- Tube forming machine

- PLC-controlled forming machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.