- Production Machines

- Forming Machine

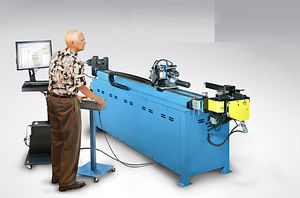

- Pipe-end forming machine

- Winton Machine Company

Pipe-end forming machine DH25metalPLC-controlledhydraulic

Add to favorites

Compare this product

Characteristics

- Product handled

- pipe-end

- Treated material

- metal

- Control

- PLC-controlled

- Other characteristics

- hydraulic

Description

Product Description

Winton's Model DH25 is a PLC controlled programmable tube end former. This end former has the ability to produce single and double hit end forms. The DH25 utlilizes a hydraulic clamp and ram ensuring that the Cp and Cpk stay on target. All cylinders, switches, relays, and valves are common in the United States, Europe and Asia.

Tube end formers typically produce a 37 degree flare, bead, double flare, or bump O-ring groove type end form. Single hit end formers are the most common and tooling is available to form a bead, expand and reduce as well as form a single flare to the end of the tube. Double hit end forms can take the shape of a double flare or a 2 stage expansion and reduction. You can utilize a die change which will enable the operator to form the end of a tube that requires 3 hits such as Aeroquip bump O-ring groove which is common with 37 degree flaring. Aerospace often utilizes double hit end forming due to the additional rigidity it produces.

All tube end formers are designed, manufactured, and tested in our Georgia facility. We use standard purchased components to build every tube end forming machine. In addition, Winton provides world class support for all of its products including its programmable end formers. Winton has produced on-line training videos to enable your operators to get educated pre and post installation. Buying a machine is one thing, it’s the post-sales support that you need to consider. Winton delivers rock solid support with every end forming machine. Winton is proud of the quality of every tube end former sold.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Winton Machine Company‘s catalogsOther Winton Machine Company products

Tube Fabrication Machines

Related Searches

- Bender

- Tube bender

- Hydraulic bender

- Electric bender

- CNC bender

- Automatic bender

- Forming machine

- Manual bender

- Mandrel bender

- Metal forming machine

- Digitally-assisted bending machine

- Compact bender

- Handheld bender

- Hydraulic forming machine

- Pipe-end forming machine

- Servo-electric bending cell

- XYZ bending machine

- Forming bending machine

- Tube forming machine

- PLC-controlled forming machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.