- Production Machines

- Forming Machine

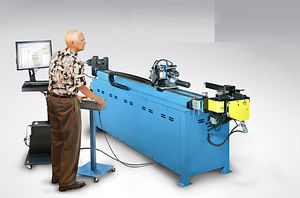

- Hydraulic bending machine

- Winton Machine Company

Hydraulic bending machine tubeautomatic2-axis

Add to favorites

Compare this product

Characteristics

- Operation

- hydraulic

- Product handled

- tube

- Control

- automatic

- Number of axes

- 2-axis

- Other characteristics

- with automated loading

Description

Product Description

The tube forming cell makes use of a linear transfer process to move the parts thru the tube forming cell. The transfer system is fed by 3 Winton high-speed loaders + a bowl feeder.

The PLC allows the overall system to change over to another part configeration in seconds.The automatic machine forms a tube and completes the assembly of 5 components 1 assembly every 6 seconds.

Tube Bending Capacity: Customer Specified

Bend Repeatability: ± 0.2°

Load process: Drop bundle of tubes/components into hopper with forklift

Cycle time: 6 seconds

User interface: Allen Bradley PV550

Walking beam: 2 axis servo driven

Bending process: precision roll bender

Microprocessor controlled via Allen Bradley

Heavy duty linear ball bearings guide all linear motions

VIDEO

Catalogs

No catalogs are available for this product.

See all of Winton Machine Company‘s catalogsOther Winton Machine Company products

Tube Fabrication Machines

Related Searches

- Bender

- Tube bender

- Hydraulic bender

- Electric bender

- CNC bender

- Automatic bender

- Forming machine

- Manual bender

- Mandrel bender

- Metal forming machine

- Digitally-assisted bending machine

- Compact bender

- Handheld bender

- Hydraulic forming machine

- Pipe-end forming machine

- Servo-electric bending cell

- XYZ bending machine

- Forming bending machine

- Tube forming machine

- PLC-controlled forming machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.