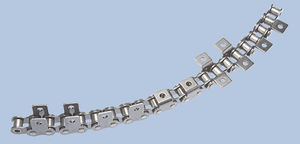

Stainless steel conveyor chain rollerrolleraccumulation

Add to favorites

Compare this product

Characteristics

- Material

- stainless steel

- Configuration

- roller

- Other characteristics

- roller, accumulation

Description

Accumulator chains are suitable for the conveyance and accumulation of piece goods, and they are usually employed for a parallel-running operation. In the standard design the chains run on a guide rail with lateral support rollers.

During the accumulation-free conveyance operation the piece goods are sitting on the conveyor rollers and are transported with chain speed, whereas during the accumulation process the chain will continue to run smoothly under the accumulated piece goods due to the freely movable conveyor rollers. Rolling friction during accumulation results in a slight impact pressure on the goods so that transportation will continue easily and without delay after the accumulation process.

Depending on the required application, conveyor rollers with different diameters and made of different materials (steel, PA 6.6, PA 12 antistatic) can be supplied.

Accumulator chains are also available in stainless steel, as Marathon maintenance-free chains as well as in duplex or triplex designs. In case of the duplex design the roller distance is only half that of the simplex design since the conveyor rollers are staggered. For long conveyance distances lateral guide plates are recommended.

The chains can also be supplied as accumulator chains AFS with AFS clips for increased operating and work safety.

Catalogs

No catalogs are available for this product.

See all of Wippermann jr.‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.