- Production Machines

- Plastics Processing

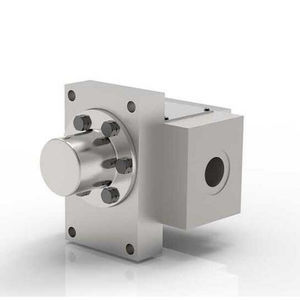

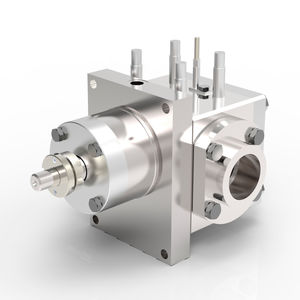

- Polymer melt pump

- WITTE PUMPS & TECHNOLOGY GmbH

Polymer melt pump EXTRU seriesgear

Add to favorites

Compare this product

Characteristics

- Type

- polymer

- Technology

- gear

Description

Melt pumps for extrusion

The extrusion gear pump is mainly used in connection with extruders or kneaders. They lower the naturally existing pulsation and uneven transportation, particularly of single-screw extruders. The extrusion pump is also used as a melt pump. It takes over the establishment of the required transport pressure, which is needed for the downstream equipment.

Efficient pressure build-up

In the gear pump, the pressure build-up occur significantly more efficiently than in the extruder itself. The extruder is relieved through the use of an extrusion pump. Significantly less energy or heat is added to the polymer. The melt pump thereby contributes to the gentlest possible transportation. The EXTRU pump is indispensable for the production of precise foils or micro-granulate.

Robust and flexible

The robust design and wear-resistant materials make the EXTRU indispensable for extrusion. It can also be used to transport natural rubber and soft PVC through different special designs.

The WITTE fast-changing color design is perfect for master batch applications with frequently changing colors.

Catalogs

No catalogs are available for this product.

See all of WITTE PUMPS & TECHNOLOGY GmbH‘s catalogsOther WITTE PUMPS & TECHNOLOGY GmbH products

Gear pumps

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.