- Hydraulics - Pneumatics

- Pump

- Gear pump

- WITTE PUMPS & TECHNOLOGY GmbH

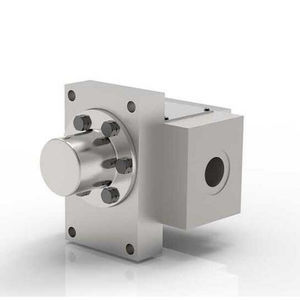

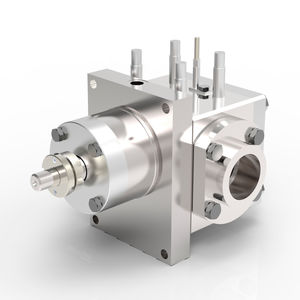

Gear pump ATpolymerfor meltelectrically-actuated

Add to favorites

Compare this product

Characteristics

- Technology

- gear

- Fluid

- polymer, for melt

- Operation

- electrically-actuated

- Priming

- self-priming

- Mobility

- stationary

- Domain

- industrial, for the chemical industry, for the textile industry, for tires

- Applications

- process, high-pressure, booster, for high-pressure applications, extra-high-pressure, for masterbatch

- Material

- steel, bronze

- Fluid specification

- for viscous fluids, for high-viscosity fluids

- Other characteristics

- high-efficiency, with flange, ANSI

- Pressure

Max.: 320 bar

(4,641.208 psi)Min.: 0 bar

(0 psi)

Description

The next evolutionary step for high-pressure pumps in the polymer process

The series is the result of a complete rework of the used core components. The customer benefits from high flexibility of design and standardization. The BOOSTER is available with flange geometries and connections that comply with EN 1092-1 and ANSI B16.5. It goes without saying that the company also offers housing variants for replacing existing pumps and debottlenecking, not to mention solutions for special requirements based on customer requests. By standardising on three gear widths for each centre distance, the distances between the respective pump sizes have been significantly reduced. This means it is now easier than ever to select the best possible – and therefore most cost-effective – pump size for each application.

The new gear geometries facilitate differential pressures of up to 320 bar for selected pump sizes. What’s more, the new design is rounded out with the usual variety of different material combinations. The most common of these combinations has to be a stainless-steel or carbon-steel housing with tool steel or aluminium-bronze friction bearings.

Advantages:

Higher efficiency, thereby

- Reduced heat input

- Energy saving = cost reduction

- Larger viscosity range

- Increased throughput of up to 40% without changing the installation size

Lower bearing temperature, leading to lower stress on the polymer

Increased safety against shaft breakage due to overload

Simplified spare part management thanks to the use of identical components for all series

Catalogs

Other WITTE PUMPS & TECHNOLOGY GmbH products

Gear pumps

Related Searches

- Pump

- Industrial pump

- Pump with electric motor

- Stationary pump

- Clear water pump

- Self-priming pump

- Chemical pump

- Stainless steel pump

- Lubricant pump

- Transfer pump

- Chemistry pump

- Compact pump

- Lubricating oil pump

- Submersible pump

- Flow pump

- Mechanically-actuated pump

- Food product pump

- Discharge pump

- Metering pump

- Work pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.