- Products

- Catalogs

- News & Trends

- Exhibitions

Oil injector QMIlaboratory

Add to favorites

Compare this product

Characteristics

- Options

- oil, laboratory

Description

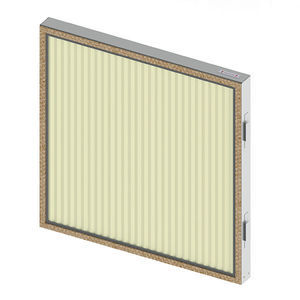

Wozair Limited manufactures the patented Quickmix Injectors, for in-situ filter testing using dispersed oil test aerosols. The QMI was designed and developed at AEA Technology’s Harwell Laboratory as an active aerosol injector to enable well mixed mist to be produced from aerosol generators. It uses the energy of compressed air to enhance the mixing of test aerosol with the ventilation system airflow. It is to be located upstream of the filters.

For industries which use hazardous or toxic materials in their processes, it is essential to regularly and accurately demonstrate filter systems continue to meet their stated performance standards. Such in-situ testing will typically be conducted under normal flow conditions and it is essential that the aerosol has mixed fully with the flow of air to adequately challenge the filter.

The advantage of the QMI over other injection methods is that mixing is achieved in short ducting lengths up to 6 duct diameters compared to more than 10 duct diameters for conventional methods such as natural mixing and Stairmand disc.

• Pressure Drop

• The QMI will usually be permanently installed within the duct. For a 350 mm diameter duct with an airflow of 950 l/s, which is representative of a standard single circular HEPA filter housing, the duct velocity is approx. 10 m/s. When non-operational the pressure drop is 20 Pa and when operational the pressure drop is 30 Pa.

• Volume of Injected Air

• The additional volume of air injected into the duct under operational conditions and at a duct velocity of 10m/s is approximately 1% of the ventilation system volume airflow rate.

Catalogs

No catalogs are available for this product.

See all of Wozair‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Hyvolution 2025

28-30 Jan 2025 paris (France) Stand 6D14

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.