- Production Machines

- Cutting Machine

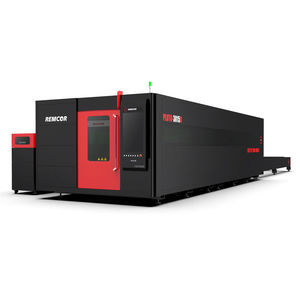

- Fiber laser cutting machine

- Wuhan Remcor Technology Co.,ltd

Fiber laser cutting machine Apollo BK seriesfor non-ferrous metalsfor aluminumfor stainless steel

Add to favorites

Compare this product

Characteristics

- Technology

- fiber laser

- Material

- for aluminum, for stainless steel, for copper, for brass, for non-ferrous metals

- Product handled

- for metal pipes

- Control type

- CNC

- Applications

- for industrial applications, for metal fabrication, for the automotive industry, for aeronautical applications, for processing industry

- Workpiece loading

- automated loading/unloading

- Other characteristics

- high-precision, high-speed, mild steel

- Tube diameter

Max.: 330 mm

(13 in)Min.: 15 mm

(1 in)- Cutting speed

80 m/min, 100 m/min

- Laser power

Max.: 6,000 W

Min.: 1,000 W

- Overall width

1,200 mm

(47 in)- Height

1,100 mm

(43 in)- Weight

Max.: 2,800 kg

(6,172.94 lb)Min.: 1,200 kg

(2,645.55 lb)2,000 kg

(4,409.25 lb)

Description

Remcor Apollo BK series three chuck tube fiber laser cutting machine can cut all types of metal tubes, from mild steel to stainless and also non-ferrous metals. It is also valid for cutting some reflective metals like aluminum, brass and copper, etc. The thickness of the metal can be anywhere up to 30 mm. The diameters can be up to Ø 350mm tubes. Can cut different shapes on the surface of square tubes, oval tubes, U tubes or rectangular tubes or other special shape tube products. The most outstanding feature of our BK system is that can realize the real Zero-tailing cutting. And our automatic loading system freedom operator from the hard and heavy pipe loading problem.

Different shapes & Different sizes

1. All kinds of pipe processing, no need to change clamping scheme.

2. Match the three-dimension head to solve all kinds of the pipe inflection points.

3. CNC and CAM can calculate complex profile sections. Φ8-Φ440 mm range.

Max weight

600kgs load and unload maximum length up to 12M.

Raw material waste

Unique 3 chucks technology, zero tailing, high pipe utilization Average material can reduce up to 30%.

Labor cost

Real time, high precision, fast troubleshooting servo motor control automatic and semi load can be chosen.

Environment pollution

Dust collection box included full sealing chuck to prevent dust into chuck to have a longer lifetime.

Low efficiency

1. Simple to operate, new upgraded system with servo motor to realize the high automation and simplication.

2. High-precision chuck to make sure high speed, stability, high quality cutting.

3. Automatic loading and unloading to improve efficiency.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Wuhan Remcor Technology Co.,ltd‘s catalogsOther Wuhan Remcor Technology Co.,ltd products

CNC Laser Cutting Machine

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Cutting machine for industrial applications

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Precision cutting system

- Aluminum cutting system

- SS cutting machine

- Metal fabrication cutting system

- CE cutting system

- Cutting machine for the automotive industry

- High-efficiency cutting system

- Steel cutting system

- Compact cutting system

- Bridge cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.