- Production Machines

- Cutting Machine

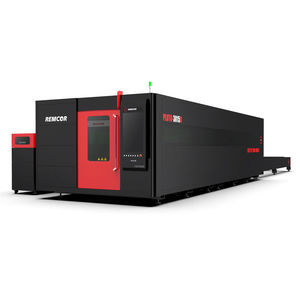

- Laser cutting machine

- Wuhan Remcor Technology Co.,ltd

Laser cutting machine Pluto PD seriesfor metalsheet metaltube

Add to favorites

Compare this product

Characteristics

- Technology

- laser

- Material

- for metal

- Product handled

- sheet metal, tube

- Control type

- CNC

- Other characteristics

- high-precision, with water cooling, fully-enclosed

- X travel

3,050 mm, 4,000 mm, 6,000 mm

(120.08 in, 157.48 in, 236.22 in)- Y travel

1,520 mm, 2,000 mm, 2,500 mm

(59.84 in, 78.74 in, 98.43 in)- Cutting speed

120 m/min

- Laser power

Max.: 6,000 W

Min.: 4,000 W

Description

If you are looking for a machine which can cut both plates and tubes, our PLUTO PD series is your best choice. The enclosed and exchangeable platforms ensures a clean and safe working environment. The working table can be designed as your requirements. The pipe cutting length can be 6m, Two 220mm chucks make it possible for processing the 80% fabrication work in the market.

• Dual-use, suitable for cutting a wider range of materials including metal plates and tubes, one machine can meet 80% of your fabrication needs.

• Creat a safer working environment. The fully enclosed type with side open doors which is convenient for inspection the working process. It's okay for American and Europe standard.

• Superior configurations. The tube welding bed, with high temperature and annealing treatment, no deformation for at least 10 years; The bed apply with the graphite anti-burning technology and dust/smoke exhaust system so that there will be almost no smoke when cutting.

• Pneumatic chuck clamping, faster in speed with higher precision.

• All the main parts can be customized with your requirements. ODM service is available.

The bed body adapts the segmented rectangular tube welding bed with fully annealed treatment at over 600⁰. After tempering, the strength, rigidity and stability are guaranteed, the precision were tested and debugged which can make sure the precision can be maintained for a long time.

Standard auto focus function, no need focus adjustment while changing sheet; Automatic tracking and accurately adjusting the focus according to the material thickness to ensure the best cutting effect of the whole board.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Wuhan Remcor Technology Co.,ltd‘s catalogsOther Wuhan Remcor Technology Co.,ltd products

CNC Laser Cutting Machine

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Cutting machine for industrial applications

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Precision cutting system

- Aluminum cutting system

- SS cutting machine

- Metal fabrication cutting system

- Cutting machine for the automotive industry

- CE cutting system

- High-efficiency cutting system

- Compact cutting system

- Steel cutting system

- Bridge cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.